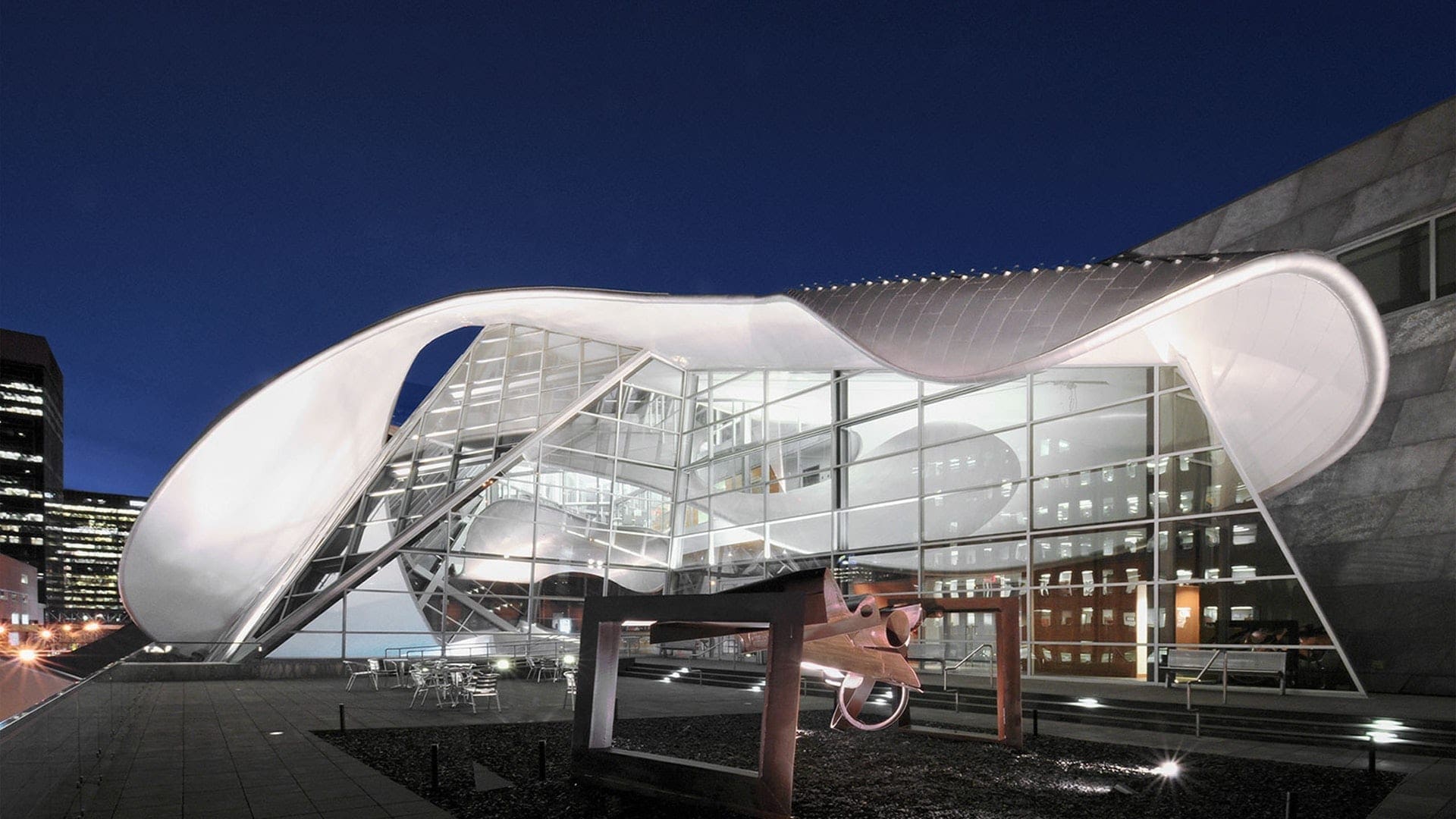

Art Gallery of Alberta in Edmonton, Canada

The Art Gallery of Alberta (AGA) is a Canadian Museum in downtown Edmonton which features a Zahner-manufactured curvilinear canopy and building envelope system. The building was designed by Randall Stout Architects with local firm HIP Architects in Edmonton.

Zahner’s scope included a massive ribbon of stainless steel which wraps around and through the building. Known as ‘The Borealis’, this curvilinear form evokes the Northern Lights, a frequent phenomenon of the Edmonton night sky. The borealis snakes through the gallery’s interior and emerges above the building to form the roof’s canopy, and then drops again to serve as a “snow cone,’ collecting snow and ice.

The sleek curving borealis is paneled in a stainless steel skin system developed by Zahner. The applied non-directional surface treatment of the metal gives the building its muted glow, reducing and nearly eliminating any harsh glare from the sun.

The ‘borealis’ is engineered using ZEPPS technology, a system developed by Zahner to simplify the construction of complex structures and facades. For a curvilinear form that wraps around and within the building, an intelligent structural system was required to handle the curves and handle all structural loads. These fully pre-assembled megapanels were delivered to the site so that the local installers could easily install the pre-fabricated panels.

The building also features a variation on the Hunter Zinc preweathered patina on zinc. This surface is used throughout the interior and exterior on flat and geometric surfaces. It is similar in appearance to slate or limestone.

Making the Art Gallery of Alberta

Zahner is one of the few organizations in the world that has a dedicated team for handling design-engineering processes. Design Assist divided the project and translated the architects’ intent into engineered subsections and parts which the draftsmen and project engineers can then rapidly push to the fabrication facility.

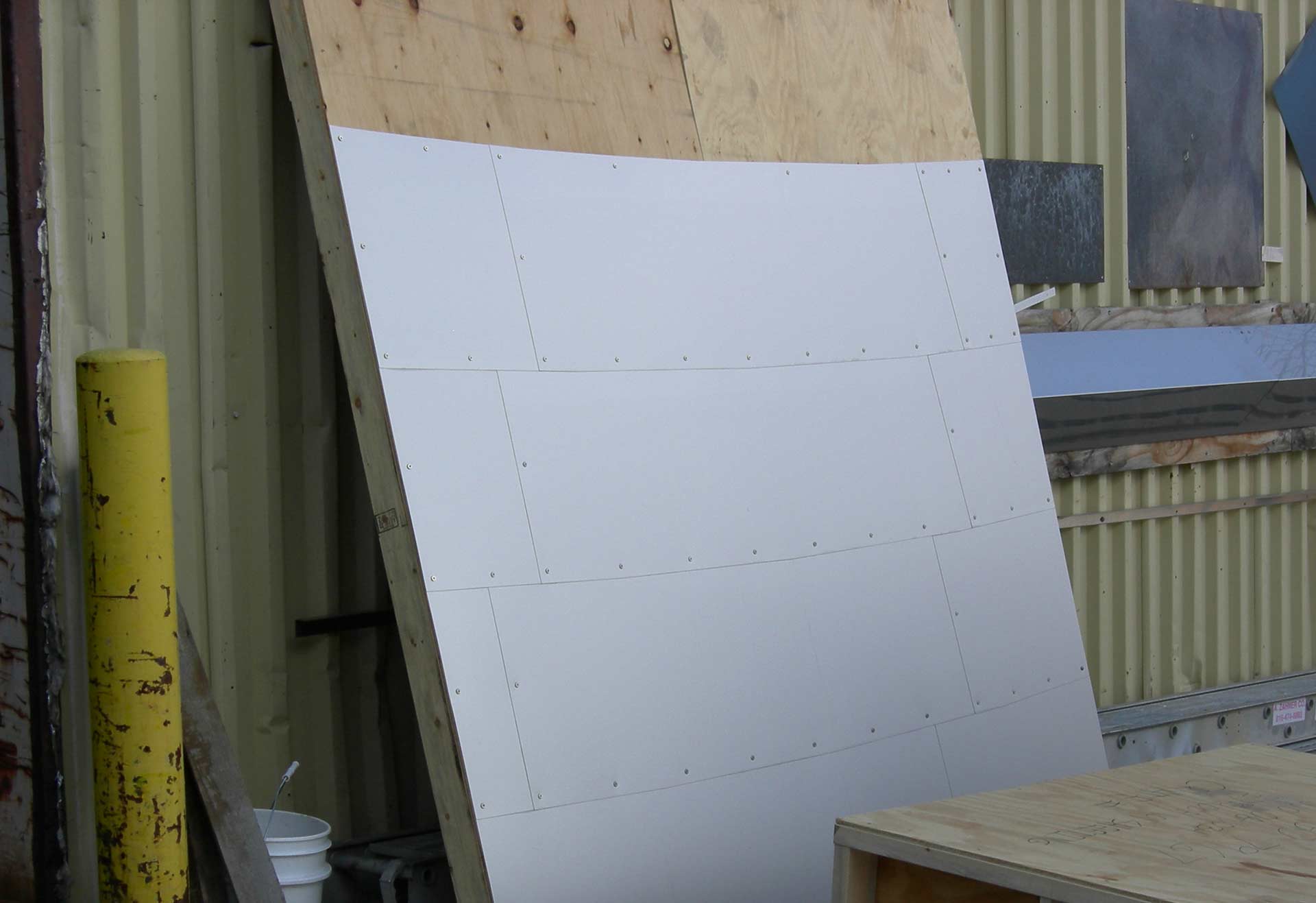

Design Assist produced several scale mockups of both the flat-lock zinc siding as well as the curvilinear Angel Hair stainless steel surface. These mockups give a sense of the upcoming quality, as well as aid in identifying potential problems and develop essential solutions.

PHOTO © A. ZAHNER COMPANY.

Zahner design-engineered, fabricated, delivered the components of the Art Gallery of Alberta for intelligent installation by the Canadian installers. This process was made possible by intensive design consulting sessions early in the planning process, facilitated by Zahner Design Assist.

Design Assist | BIM to Build

As the construction world continues to move towards digital and cloud computing, Zahner fully integrates into Building Information Modeling (BIM) frameworks, so that all participants are aware every stage of construction.

The structure for the Art Gallery of Alberta was divided into several complex components, and to keep the entire project organized required a strong BIM foundation. Drawings from the architect were digitally defined and refined into a working model which served to involve every aspect of its construction.

This makes complex components, such as the architectural metal wing flying through the window, possible (see below). Coordinating multiple trades is one of the big strengths of BIM. It also plays a large role in condensing the construction down to its essentials.

PHOTO © A. ZAHNER COMPANY