APPLICATIONS

Explore Zahner’s project portfolio through specific building features and typologies.

Building Envelope

Total Wall, Roof, and Fenestration Systems

Roof

Flat, Curved, or Dual-Curved Roof Systems

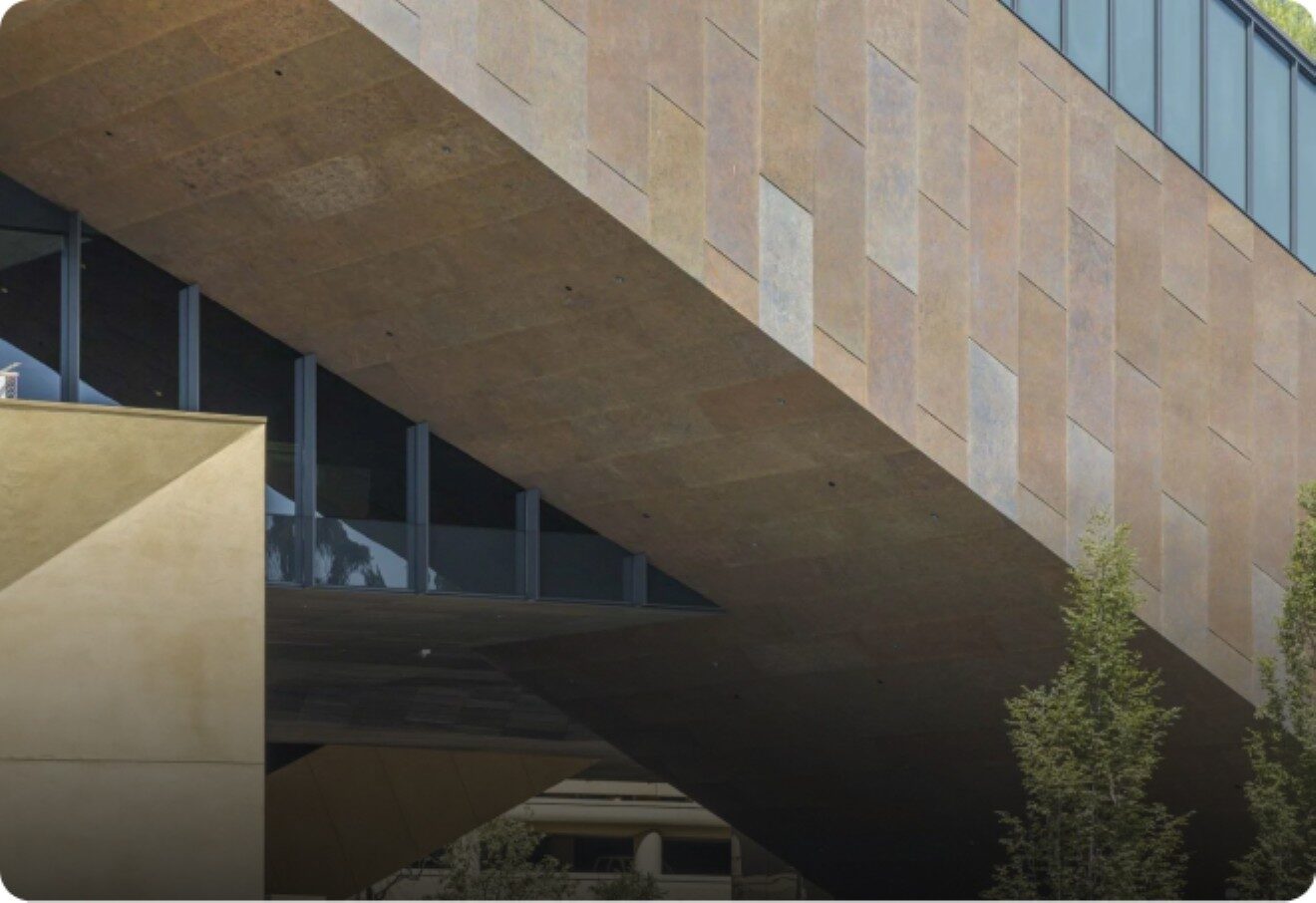

Soffit

High Performance Overhangs

Canopy

Entryway Awnings & Free-Standing Canopies

Column Cover

Decorative Column Cladding

Fin Facade

Louvered Light & Air Control

Entryway

From Awnings to Interiors

Grate & Planter

Custom Plant Surrounds

Guardrail

Add Beauty to Function

Mullion & Transom

Horizontal & Vertical Member Cladding

Signage

From Branding to Wayfinding

Facade / Wall

Interior & Exterior Wall Systems

Ceiling

Custom Overhead Systems

Parking Structure

Facades for Parking Structures

K-12 Architecture

Metal Surfaces, Signage, and Perforated Panels for Schools

Perforated Metal Panels

For Facade, Feature Wall, and Screen