Patents

Zahner-Patented Systems and Technologies

Patents developed by A. Zahner Company include a range of technologies, from a method for producing images and patterns on metal, to the hardware used to make curvilinear forms, to the perforated image generators used to speed up the process of making unique architectural facades and more. Zahner engineers and fabricators use the patented technologies to provide support for projects around the world. The patents below protect the innovations and research developed by Zahner employees, providing the architectural industry with new standards for tomorrow.

IMAGES © A. ZAHNER COMPANY.

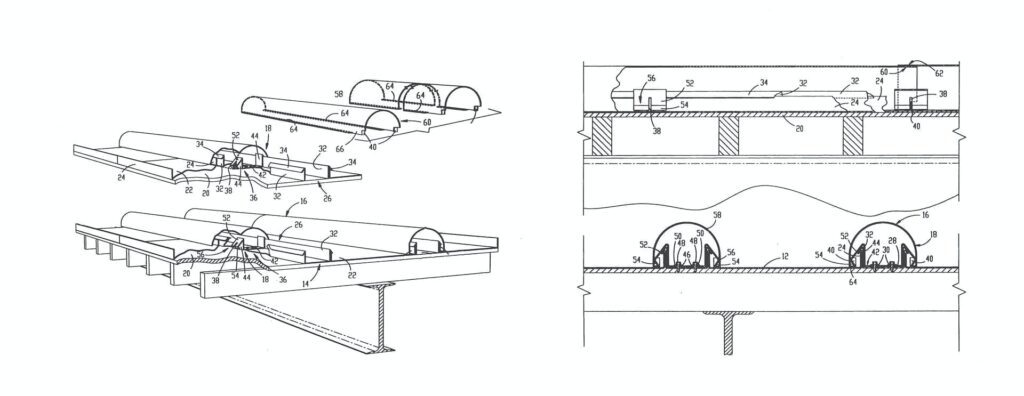

Inverted Seam® Patent

PATENT US 20070175157 A1

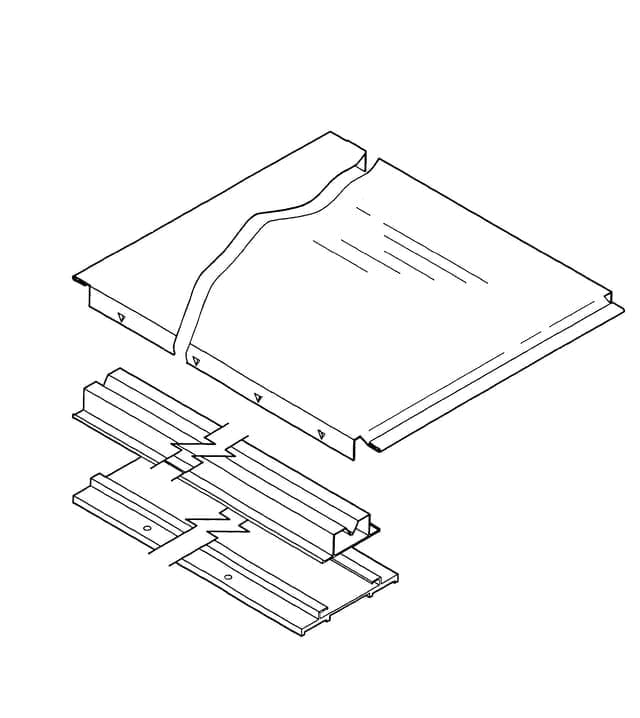

The Inverted Seam patent is used in a number of Zahner metal products. Primarily used for both roof and wall enclosures, these systems provide an advanced degree of protection from moisture. Inverted Seam roof systems can be installed at near-level pitches because of its sub-surface drainage channel, enabling architects to design for flat roof systems with a uniform metal appearance.

The Inverted Seam is a panel attachment system which includes the exterior panels, the retaining members, and mounting structures which secure the system. The panels are held to the retaining members through the use of protruding locking members formed on the panels which interlock with a slot formed on the retaining member. The panels may be coupled to the retaining members without the need for precise alignment, thereby expediting the installation of the surface. The retaining members additionally contain a drainage channel to carry water and other debris away from the surface.

IMAGES © A. ZAHNER COMPANY.

ZIRA ImageWall® Patent

US 7212688 B2

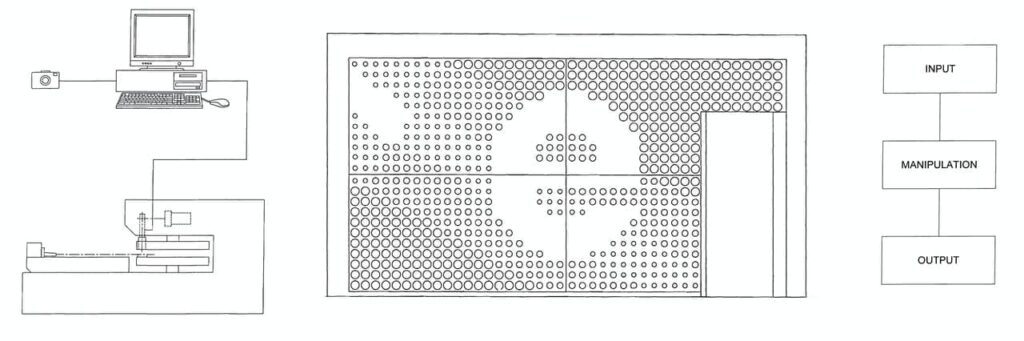

A method of transferring a representation of an image to a surface of a building. The method comprising receiving the image as an image file, converting the image file to a raster file comprising a series of dots, scaling the raster file to the surface and dividing the raster file into a plurality of sub-components, associating the dots with markings, and transferring the markings onto a plurality of metal sheets. The system is used by a number of Zahner products and systems, including ImageWall for custom perforated metal, Louvered ZIRA, and custom ZIRA applications.

The markings may be indentations, holes, and/or bumps. The dots may be manipulated to accommodate features of the surface, such as windows, doors, indicia, and edges of the sheets. The markings are preferably transferred to the sheets by a metal working machine. Thus, the method may include generating one or more control files that may be used by the machine.

IMAGES © A. ZAHNER COMPANY.

Angel Hair® Zahner Patent

US 20100233942 A1

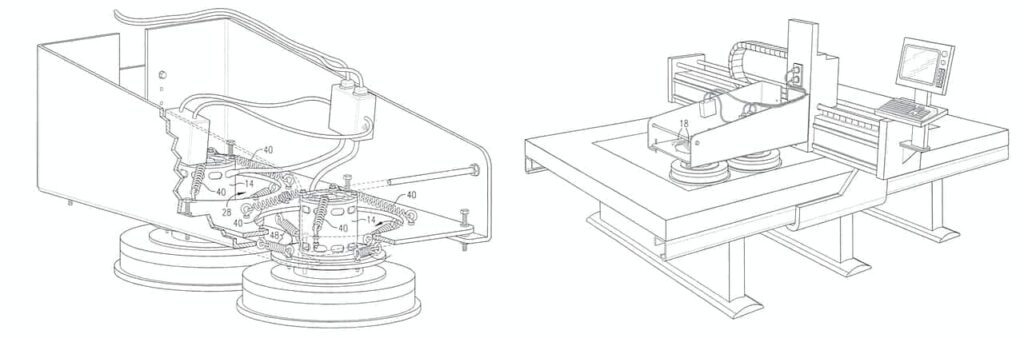

A patented fabrication system for producing Angel Hair non-directional finishes on metal surfaces. An apparatus for applying a lightly scratched surface to a metal sample comprises a motor, a disk, a frame, a motion guidance unit, and a plurality of springs. The motor may provide a rotational motion to the disk which includes abrasive elements configured to create a plurality of microscopic scratches on the surface of the metal sample.

ShopFloor® StoreFront System Patent

PATENT PENDING US 14/839507

An addition to the ShopFloor patented systems developed by Zahner. The patent includes a replaceable curtainwall system for metal coverings and window supports. System assembly includes aluminum framing, glass inset, and assorted exterior mullion cladding in a variety of metal surfaces.

Omni-Directional Connection Assembly Patent

PATENT US 9482267 B1

A component addition for ZEPPS patented assemblies which provides universal omni-directional connections for panel attachment. The omni-directional connection assembly includes a hinge pin and one or more connection brackets.

IMAGES © A. ZAHNER COMPANY.

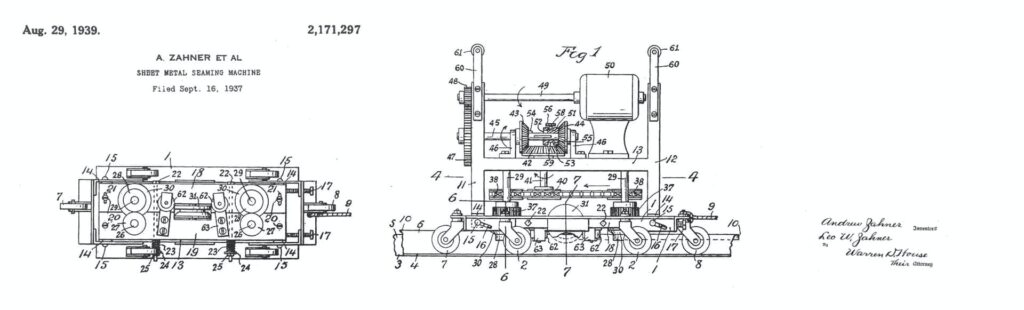

Historic Patent for Sheet Metal Seaming Machine

PATENT US 2171297 A

A historic Zahner patent awarded in 1937 for improving speed of seaming sheet metal roof systems. The system provided a double-layer standing seam roof, at a rapid speed for producing massive roof systems.

The machine about the size and weight of a cast-iron bathtub, and was rolled around the roof to seam roofs on large-scale projects. The machine is no longer used. Zahner has since developed more efficient and effective roof systems for buildings.

IMAGES © A. ZAHNER COMPANY.

Bold Batten Roof System Patent

PATENT US 5272849 A

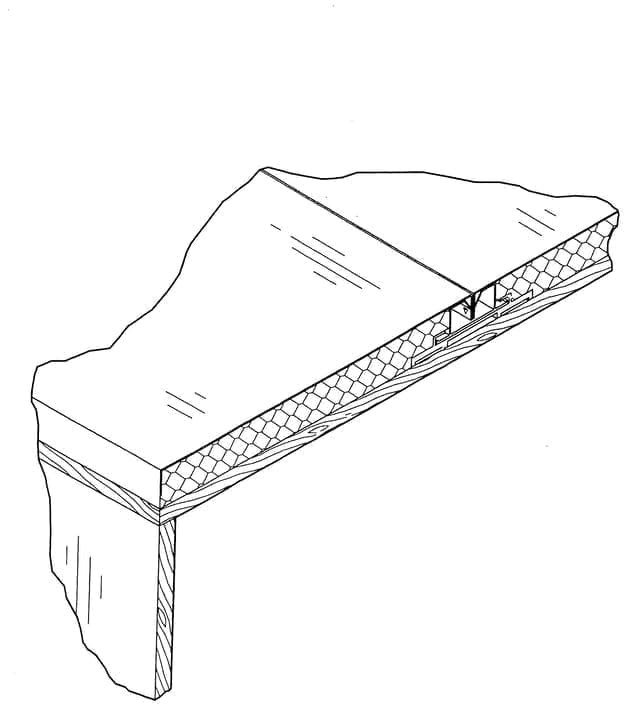

The bold batten roof patent is a complete weathertight roof system with no exposed fasteners which prevents longitudinal movement between joints and covers. Previous fastener systems developed by architectural industry had issues with thermal expansion, in part due to the fastening system. This system solves these issues and others, providing a cleaner aesthetic for bold batten roofs.

An improved roof covering system includes roof panels, joint areas, joint covers, and securing assemblies. The joint covers include transversely extending locking tabs. The securing assembly includes clips having vertically oriented slots for engaging the tabs. The cover is thereby secured over the joint in weathertight relationship without the use of exposed fasteners while preventing longitudinal movement between the joints and covers.