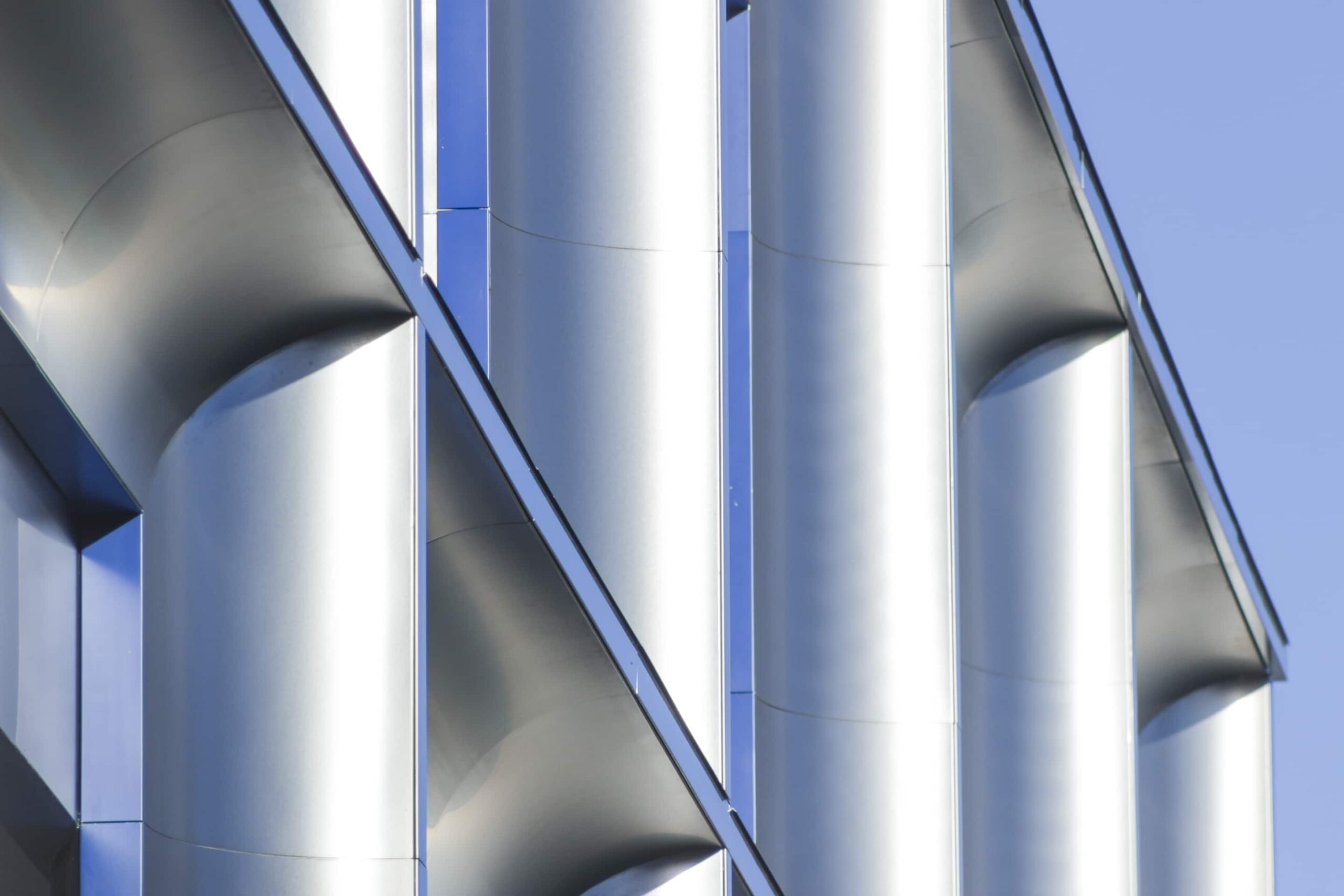

Stainless steel is a naturally reflective metal that has the added benefit of corrosion resistance. It offers infinite variations of finishes and textures that can be mixed, layered, etched, and embossed to create a surface appearance like no other. When you also consider the hardness and durability of stainless steel, you can see why it is considered the king of architectural metals.

Because of its chrome content, stainless steel reflects 49 percent of the visible wavelength of light. It is much more heavily weighted toward the blue wavelength and captures well the tone of the sky. On cloudy days, stainless steel will appear with very little luster.

Ohr O’keefe Museum Pods Designed By Frank Gehry Partners.

Photo © A. Zahner Company.

Ohr O’keefe Museum Pods Detail, Designed By Frank Gehry Partners.

Photo © A. Zahner Company.

It is the nature of how light reflects from a surface that makes stainless steel attractive to the designer. The reflective character of the various stainless-steel finishes can be divided into three categories; Reflective, Diffused Reflective, and Low Reflective.

- Reflective Finishes can be described as those that reflect light similar to a mirror. A bright light will reflect as a “hot spot” and very little scattering of light occurs.

- Diffused Reflective Finishes are produced when disturbing the even reflective surfaces with minute surface fractures or indentations, which scatters the reflected light slightly. Because these finishes are typically applied over the Reflective Finishes, they possess a brightness, an almost glowing behavior when in strong light.

- Low Reflective Finishes possess a dull reflection. Light is effectively scattered by the rough surface and these surfaces appear flat in most light.

Perforated stainless steel facade by Zahner

Photo By Tex Jernigan | Arko © A. Zahner Company.

Along with its remarkable reflectivity, stainless steel is durable. One of the few metals expected to stand against nature and not change in perceivable ways, stainless steel is homogeneous in its makeup. Scratch it, cut it, or pierce it, and you have the same stainless steel throughout. It does not require other metals to protect it, nor does it need paint to seal its surface from the rigors of the environment.

This durable and jewel-like metal is synonymous with the modern age (art conservationists consider stainless steel one of the so-called modern metals) and it adorns building facades and roofs on many major structures around the world.