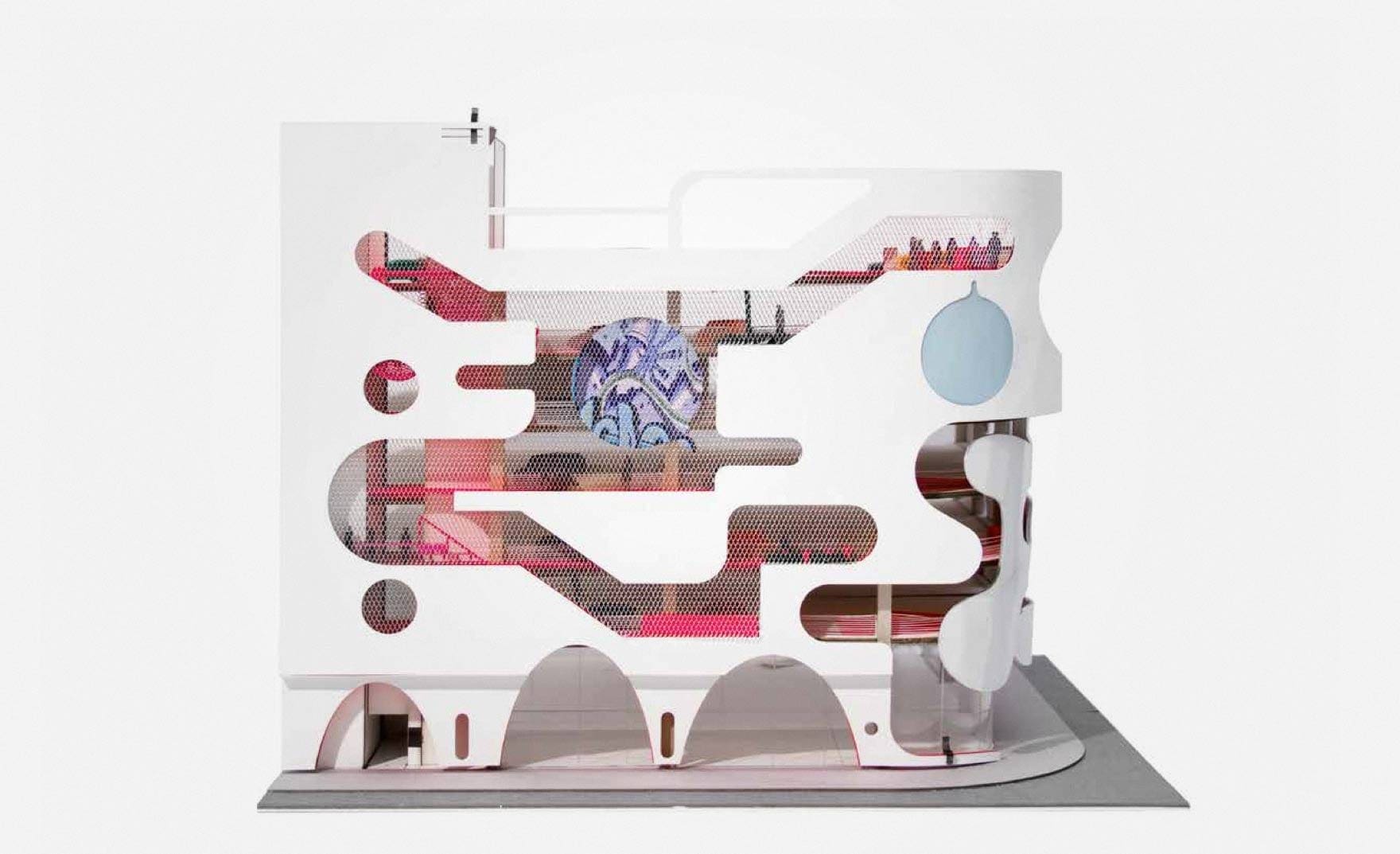

The Museum Garage is a seven-story mixed-use retail and parking structure located in Dacra’s Miami Design District. Featuring five dramatically different architectural facades and a painted mural, the project celebrates diverse creativity in keeping with the development’s emphasis on innovative experiences in shopping and dining.

Terence Riley of K/R curated the project’s unique aesthetics recruiting designers from WORKac, J.MAYER.H, Clavel Arquitectos, Nicolas Buffe and K/R (Keenen/Riley). Each of these designers approached their part of the structure with a wholly unique vision, custom engineered and fabricated by Zahner.

Complex Projects Begin with Design Assist

Each facade began with the Zahner Assist solution, a methodology of working collaboratively with design teams to bring each unique vision to reality. This unique Design Assist process involves deep critical thinking of all project aspects, assuring constructability, safety, and aesthetic requirements are met. This step is crucial in discovering and solving issues that could arise in the shop and field, reducing the number of change orders and remaining within a project’s budgetary parameters.

WORKac : More Than a Facade

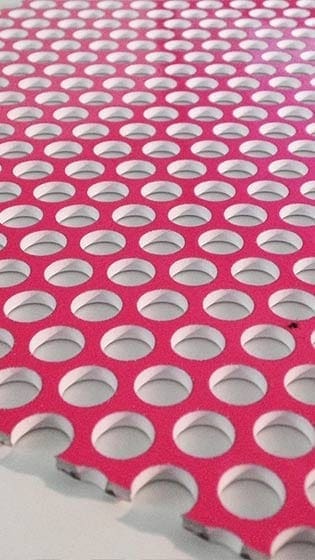

New York–based WORKac designed the east facade, which wraps the corner onto the north elevation. Meandering walkways are concealed and revealed through precisely placed perforated aluminum panels, themselves creating shapes from the resulting negative space. Each panel is painted white on the exterior and a vibrant pink on the interior. The concrete substructure, painted in the same pink hue, becomes part of the overall design. The intent is to reveal glimpses of the activities taking place behind the screens, including a DJ booth and street art space among others.

The project presented several design challenges, which Zahner and the WORKac team solved during the Zahner Assist process:

- Complex geometry around the various radii and at the ground tier

- Anchorage solutions for the complex structure

- Solving for non-continuous mullions

- Two color, double-sided painting on perforated aluminum

PHOTO © A. ZAHNER COMPANY

J. Mayer H. : XOX

The Berlin-based practice of J. Mayer H. created XOX, a facade that translates the voids created in the WORKac elevation into volumetric, puzzle-like shapes fabricated in aluminum with Zahner engineered structural forms. These shapes are painted with stripes of black, blue, and red patterns similar to those found in the far north facade designed by K/R. According to the K/R website, the collaborative nature of designing a facade alongside other creatives is “an exciting innovative design strategy to explore collaboration, adjacencies, and cross-referencing.” This portion of the project features embedded lighting on the perforated elements, imbuing the structure with an otherworldly glow.

During the Zahner Assist process, Zahner’s ZEPPS technology and Drop and Lock systems were combined to achieve the project’s aesthetic. The development of the system enabled pre-skinning of all elements which allowed for shop-level control of the curved, multi-colored painted artwork.

Nicolas Buffe : Serious Play

Nicolas Buffe, a French artist based in Tokyo, designed Serious Play. The facade references Buffe’s studio practice, which is based on a

multi-faceted interpretation of erudite and popular culture. The

juxtaposition of classical and contemporary cultural references draw

upon the humanist notion of Serio Ludere, meaning ‘to play seriously,’ hence the work’s title.

Zahner fabricated the cartoon, baroque inspired images. Each section is cut from black and white layered HDPE and milled to reveal the artist’s signature drawing style. The shapes are attached in varying standoff dimensions, achieving the artist’s intent of visual depth.

Through the Zahner Assist process, Zahner developed two custom systems that achieved the artist’s intent of visual depth. These standoff systems were integrated with the Drop & Lock panel system that acts as a white canvas for Buffe’s drawings. Many of the artwork elements have pre-attached luminaires behind them. Zahner solved for this by coordinating CNC cut paths on the reverse of the art pieces.

Clavel Arquitectos: Urban Jam

Clavel Arquitectos, based in Murcia and Miami, drew inspiration from the area’s urban growth with their facade, Urban Jam. The design features 36 car shells painted in silver and gold. The car shells were fabricated by Entech Innovative and engineered to attach securely to the facade by Zahner.

Keenan Riley (K/R) : Barricades

Keenan Riley (K/R) designed Barricades, a facade inspired by parking barricade stripes. The orange and white striped triangular extrusions, some perforated and illuminated, are disrupted by varying sizes of protruding painted concrete planter boxes. Each planter box is surrounded by a mirror polished, stainless steel “picture frame”.

Through the Zahner Assist process, the sloping slab of the parking structure was resolved with the rectilinear facade design through a secondary steel system that spans horizontally between concrete columns. This allowed the triangle extrusions to be shop-assembled, with mating head and sill extrusions, into units optimized for shipping and installation.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.