Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

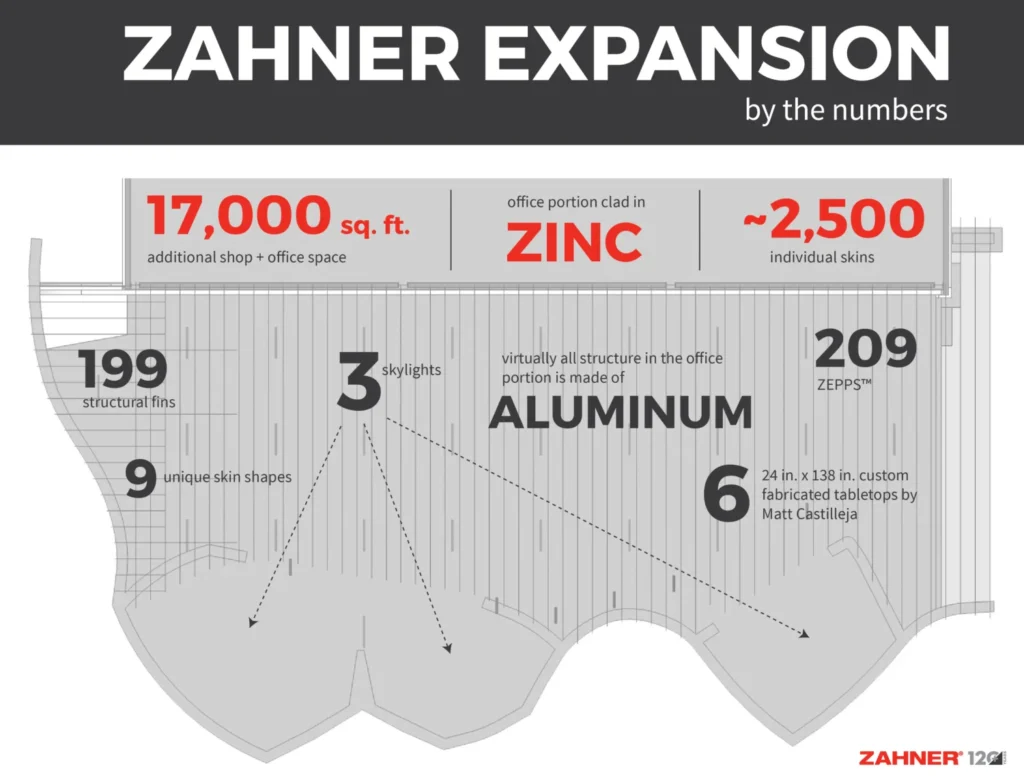

While worldwide demand for exceptional metal art and architecture is increasing, our headquarters has been feeling too small for our growing creative staff. Engineers from sales, research and development, product development, planning, advanced fabrication, and other disciplines are now collaborating in over 17,000 square feet of expansive space designed to encourage interactions inside while piquing the interest of those outside looking in.

“We’re proud to share this first look at the new expansion we built to showcase our collaborative force and create a space we hope will inspire artists and architects to visit often.

– Bill Zahner, CEO, Zahner.

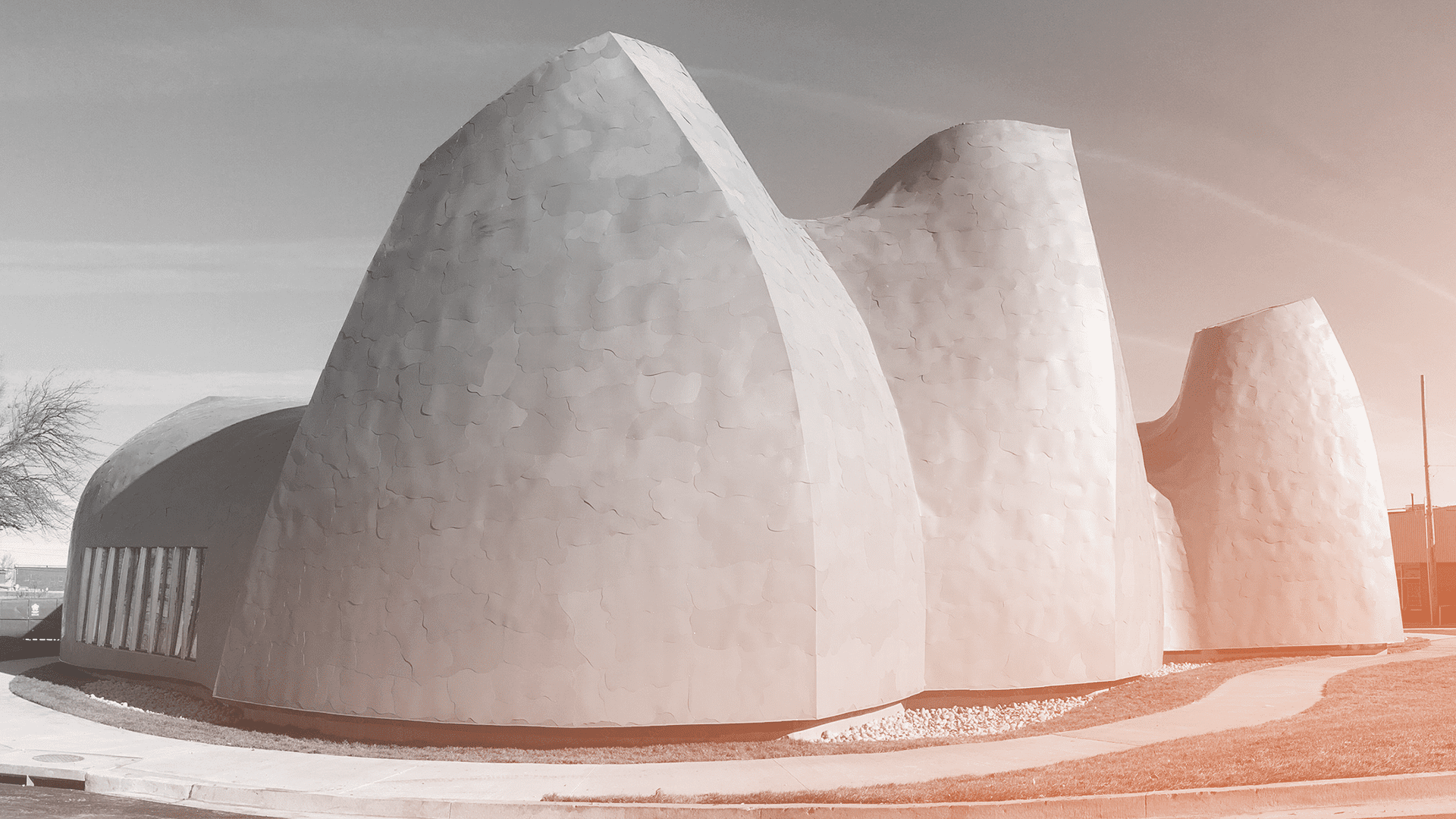

Crawford Architects designed the building’s exterior form, which is loosely based upon a common theme often seen in still life composition: the juxtaposition of three similar items. Three vertical ‘pods’, serving as a conference room and co-joined work spaces, rise directly east of the existing main building in homage to this classic tableau. Each pod melds into a gently sloped roof, sheltering the interior office area, which connects to a more traditional, box-like shop space for fabrication of special projects.

PHOTO © A. ZAHNER COMPANY

The office portion of the building, along with each pod, is clad in amorphous zinc panels (9 unique shapes in total), lending a curious, scale-like texture to this portion of the structure. The shop area cladding is a more conventional insulated metal panel system. The result is a dichotomy of traditional and contemporary aesthetics.

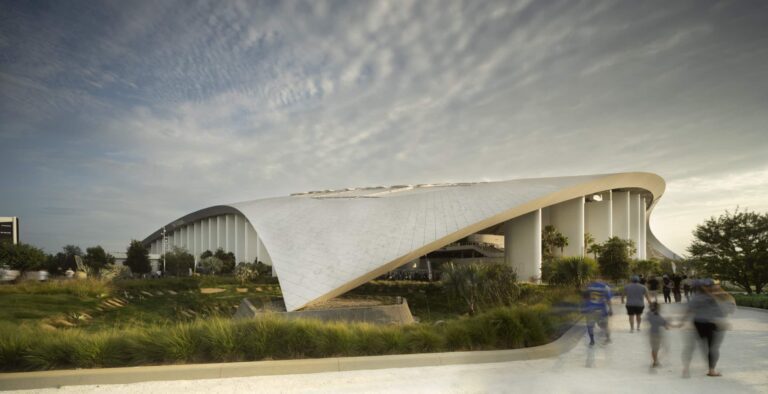

Still life composition inspired the building’s exterior, but the interior is anything but static. The space is open, airy and visually dynamic – qualities meant to facilitate collaboration and interaction among shop and office employees alike.

“The feel of the space will inspire the creativity our team needs to turn our client’s designs into reality.”

-Jim Mendenhall, Production Engineer Manager, Zahner.

A large wall of windows, spanning floor to ceiling, allows an unbroken visual connection between the office and shop areas, providing transparency—quite literally—into the full stack of the Zahner creative workflow.

PHOTO © A. ZAHNER COMPANY

“The connection of the office and shop – in proximity and visibility – will encourage increased engagement between engineering and manufacturing, resulting in efficiencies we can pass on to our clients.”

– Tom Zahner, COO, Zahner.

Natural light filters into the office area through three skylights atop each pod, a bank of windows on the west facing facade and a large-windowed curtain wall facing east. Clerestory windows on the north, west, and east elevations light the shop space.

Structural ribs, which form the building enclosure, are intentionally exposed inside the office area. These ribs, called ZEPPS, are part of the Zahner system for creating complex curved forms and are usually covered by material selected to form the building skin. In the new space, however, the ZEPPS are incorporated into the design aesthetic, undulating across the ceiling and down the walls. The space seems alive – moving and changing depending on one’s orientation within.

PHOTO © A. ZAHNER COMPANY

Photo © A. Zahner Company

Employees share custom wooden work surfaces. Matt Castilleja, a Kansas City based furniture designer, hand-crafted each tabletop surface from 15 strips of Ash, Poplar, and White Oak. Zahner engineers collaborated with Castilleja to design and attach the metal bases. Introducing wood surfaces into the space further enhances the natural beauty of all materials used.

“I’m excited to work in a space I helped engineer and to see how working within it will lead to new perspectives.”

– John Brennan, Project Engineer, Zahner.

Holistically, the new building is reflective of where Zahner is headed in 2018 and beyond. We will be encouraging our clients and colleagues in the art and design communities to visit often to learn, collaborate on projects, and be inspired. We hope you will find time to visit us in our new space in 2018!