Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

While it’s sometimes possible to order custom sheet sizes directly from a mill, that path comes with longer lead times and minimum quantity requirements. If scope and design allow, working with standard sheet sizes is the most efficient way to maintain both schedule, budget, and quality.

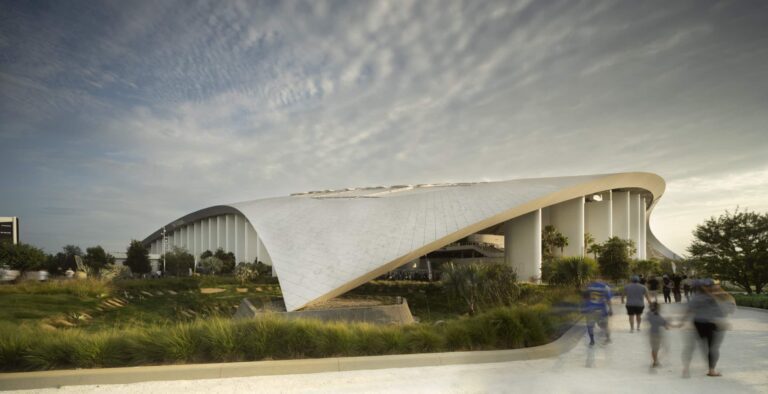

PHOTO © A. ZAHNER COMPANY.

PHOTO BY JEREMY PURSER, © A. ZAHNER CO.

Know the Standard Sheet Sizes

At Zahner, we offer a wide range of architectural metals, each with its standard sheet sizes. These sizes are readily available and form the basis for efficient material layout.

Standard Sheet Sizes Include:

| Material | Widths (in) | Lengths (in) |

|---|---|---|

| Weathering Steel (A606/A588) | 48, 60, 72 | 96, 120, 144 |

| Stainless Steel (SS304/SS316) | 48 | 120, 144 |

| Copper | 36 | 120 |

| Zinc | 39.4 | 120 |

| Aluminum | 48 | 120, 144 |

Using these dimensions as the basis for your panel layout can significantly reduce waste and unnecessary costs.

Photo © Scott Moore.

PHOTO © A. ZAHNER COMPANY.

Understanding the Finer Points of Material Dimensions and Material Usage

Our Flat Seam Panel System involves alternating up-and-down hemmed edges on each panel. This adds roughly 3 inches to both the width and height of each panel beyond the visible surface.

For example, if your design calls for a 24″ x 72″ face dimension, the actual sheet metal cut will need to be 26.25″ x 74.25″. If you’re using a 36″ x 96″ copper sheet, this panel size may result in significant leftover material that cannot be reused, driving up both cost and waste.

By adjusting your panel dimensions slightly, without compromising your design intent, you can often nest more panels per sheet and boost yield.

Sample Yield-Optimized Panel Sizes for Flat Seam

Some efficient, low-waste panel size examples that nest nicely on a 36″ x 120″ copper sheet include:

- 20″ x 31.5″ (5 per sheet, rotated)

- 13.875″ x 36″ (6 per sheet)

- 30″ x 36″ (3 per sheet)

- 13.875″ x 115.5″ (2 per sheet)

These sizes account for hemming, kerf spacing, and other factors to ensure optimal material yield.

PHOTO © A. ZAHNER COMPANY

Balancing Panel Size with Labor and Appearance

Choosing the ideal panel size is a delicate balancing act between minimizing material waste, reducing fabrication labor, and maximizing aesthetic impact.

- Smaller panels reduce material waste but increase labor for fabrication and installation.

- Larger panels reduce labor but may result in more scrap material and potential surface distortion (like oil-canning).

- More seams from smaller panels can increase the ratio of hemmed, overlapping material, which may reduce visual surface area efficiency.

We help designers evaluate these tradeoffs and propose layout options that make the best use of selected materials.

Understanding the Oil-Canning Effect

Oil-canning, a visible waviness or surface distortion, can occur more readily in larger panels or thinner gauges. While some designers appreciate how the texture and irregularity create an undulating, active surface — others aim to minimize it.

The best way to confirm your preference is through full-size mockups or test panels. This allows you to assess how the metal behaves under lighting conditions and in different orientations before committing to a whole facade.

PHOTO © A. ZAHNER COMPANY.

Use Non-Directional Finishes to Your Advantage

All Zahner patinas and mechanical finishes (like Angel Hair® or GB-60™) are non-directional, which means panels can be rotated during layout and nesting without affecting the overall look. This dramatically improves your ability to optimize material usage.

Directional finishes (such as a No. 4 brushed stainless) limit this flexibility and often result in more waste.

We Can Help, At Any Stage

Our team is happy to assist with panel layout studies during your design process. We can:

- model panel nesting to maximize yield;

- explore variations in panel size and joint layout;

- evaluate finish direction, gauge thickness, and stretchout impact; and

- compare options in terms of material cost, labor, and appearance.

We’ve done this for countless projects, from the striking Star Blue™ Copper at SUNY New Paltz to the Baroque™ Zinc brick-style layout at Max Brenner Chocolates in Bethesda. These projects demonstrate how thoughtful panel planning yields beautiful, cost-effective results.

PHOTO BY TEX JERNIGAN, ARKO | © A. ZAHNER COMPANY

PHOTO © A. ZAHNER COMPANY.

Ready to Get Started?

Whether you’re just starting your design or finalizing drawings, it’s never too early to explore your best-fit panel sizes and patterns. Our team can work with you to:

- align material usage with budget;

- recommend panel sizing that fits aesthetic goals;

- prevent costly last-minute value engineering changes; and

- preserve the full beauty of your preferred metal and finish.

Can panel sizing improve your design and budget? Contact us to start a custom layout study.

Looking for more on material options, panel sizing, or Flat Seam panels?