Drop & Lock™

Panel Attachment System

Drop & Lock enables fast and sealant-free installation of metal panels and other hardware for architectural metal systems.

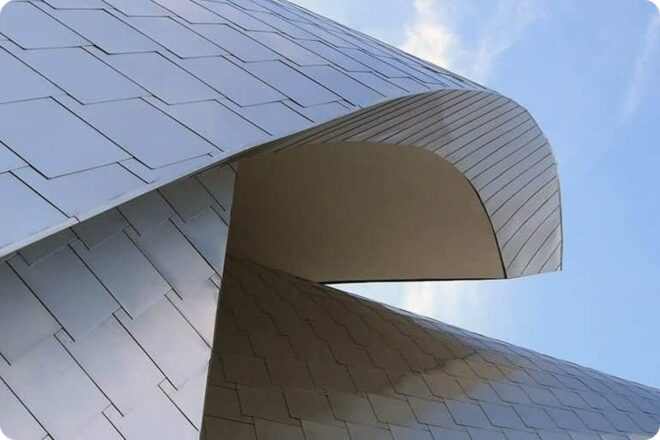

Drop & Lock Inspiration.

Drop & Lock Inspiration.

Finishes

Finishes

These Zahner Surface are compatible with Drop & Lock.

Request a Sample

About Drop & Lock

About Drop & Lock

© A. Zahner Company

© A. Zahner Company

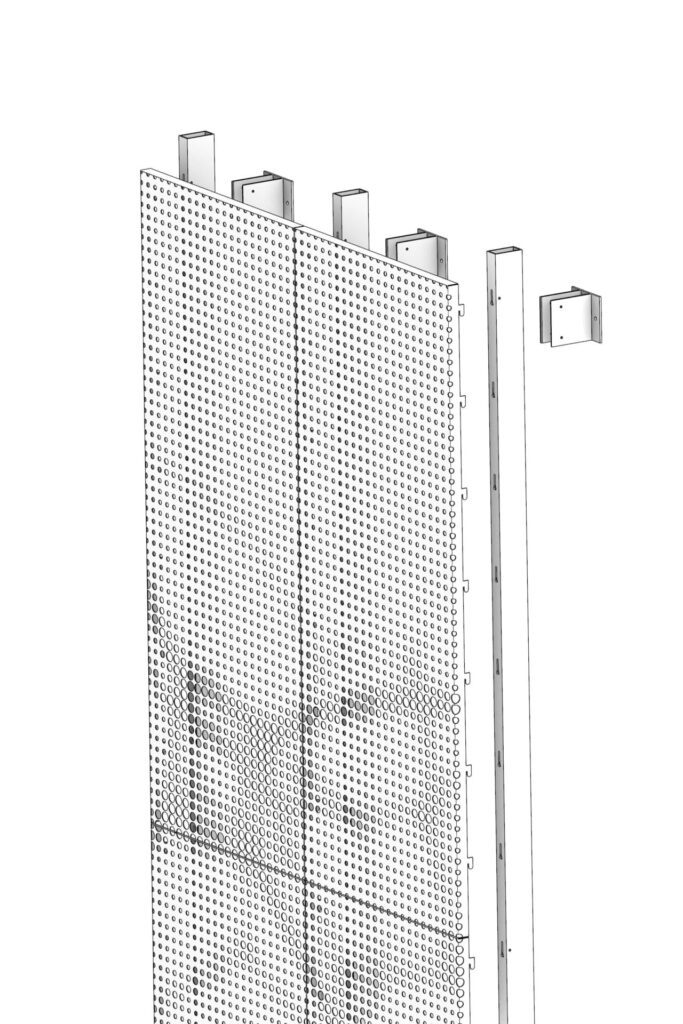

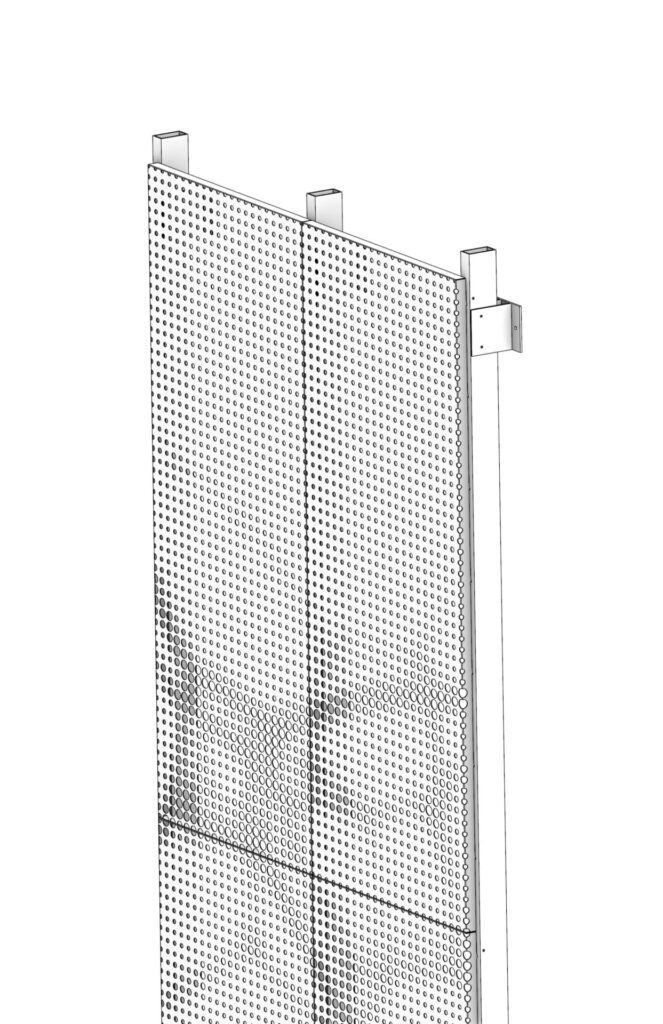

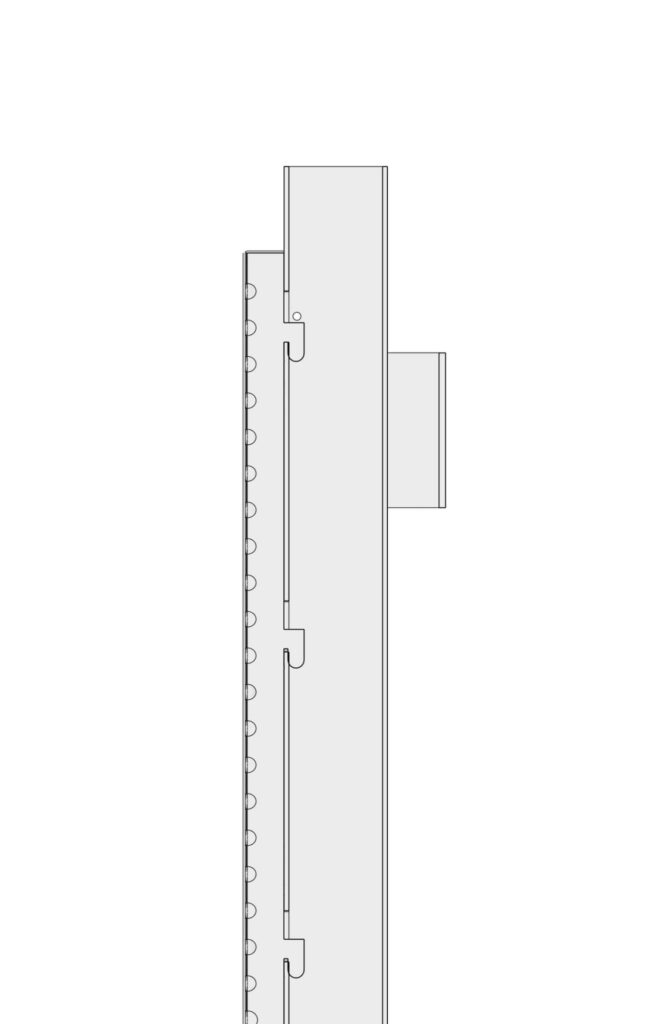

Drop & Lock comprises panels with returns that engage into vertical mullions using interlocking components. Once the mullions are laid out and in place, the panels are easily mounted. Installers lift the panels into position, insert L-shaped prongs into corresponding slots in the mullions, and drop them into place. The shape of the prongs and gravity immediately lock the panels into the mullions.

Great for any vertical wall application, we help your team choose the best material, surface treatments, panel sizes, and joint patterns for your project’s design and budget.

Benefits

Installation: Quick and easy installation without need for special tools

Material Usage: Panel sizes can nest efficiently into raw material sheets

Removable Panels: Panels can easily be removed and replaced

Concealed Hardware: No visible fasteners; no visible backside weld transfer

Lower Engineering Effort: Details & specifications reduce engineering time

Downloads

Downloads

Featured Projects

Featured Projects

About Products & Systems

About Products & Systems

Learn how to purchase and specify Zahner products and systems.

Zahner Standard Products are ready-to-order solutions.

From Zahner’s signature metal Surfaces to the Moda modular wall panel system, Standard Products are cost effective options to bring extraordinary impact, material quality, and performance to projects with ordinary budgets.

Zahner Versatile Systems are pre-engineered solutions that are ready to specify.

They are the perfect way to get ready-to-install Zahner Surfaces, without the time and costs required for a custom-engineered solution.

Versatile Systems can be adapted to fit your project requirements, typically offering multiple options for panel sizes, shapes, and joint layouts

The Zahner Custom Solutions team drives project innovation through collaboration with designers, architects, and artist.

Custom Solutions leverage Zahner’s full capabilities, services from pre-design to installation, and even R&D — all aligned to deliver on your most ambitious vision.

Take the Next Step with Drop & Lock

Build the Incredible with Drop & Lock

Bring the beauty and performance of Zahner’s metal surfaces to your project with Drop & Lock.