Zinc has been in use as an architectural cladding material for many decades. Either in the commercially pure sheet form or as the ubiquitous coating on steel, typically referred to as galvanized steel.

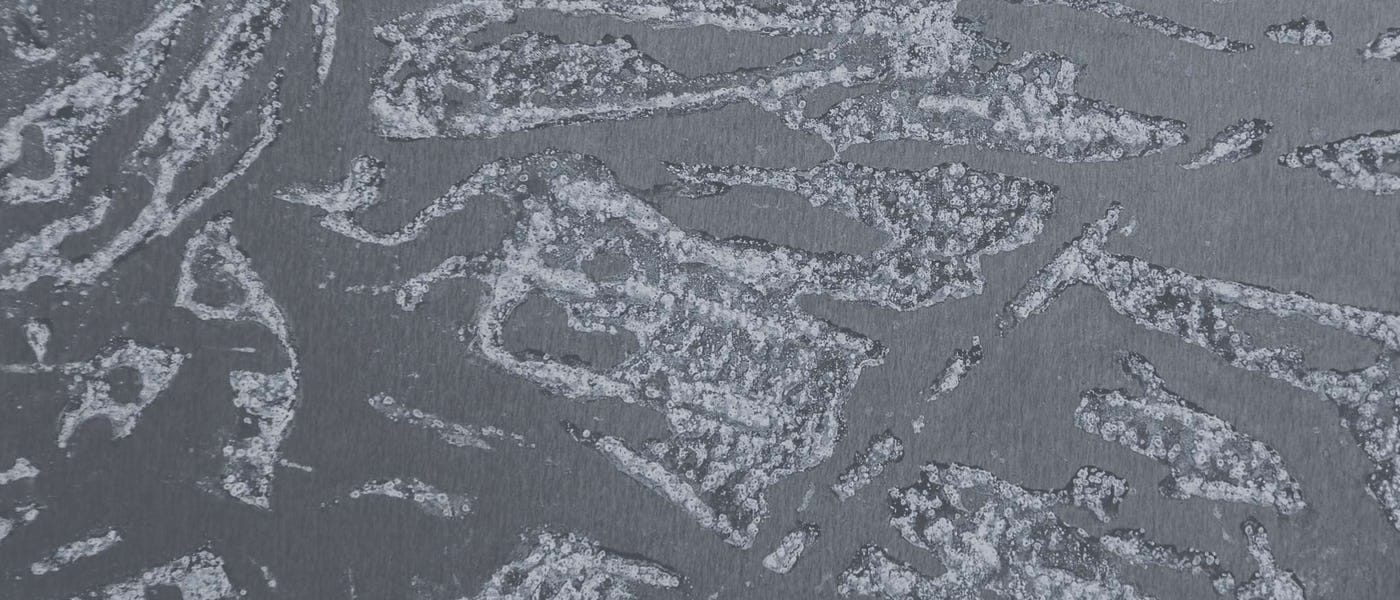

In its natural state, zinc is a bluish gray metal. In the commercially pure form, zinc is available in various sheet sizes, castings, and small cross-section extrusions.

The mill surface is a bright, finlike appearance. It has a silver color. Mill-finish zinc quickly weathers to a dull blue-gray color as it develops zinc hydroxide over the surface. In most instances, the zinc hydroxide quickly forms a surface of zinc carbonate. Zinc carbonate offers excellent corrosion protection to the base metal. The pleasing color develops quickly in most exposures. Coastal exposures develop a chlorinated hydroxide with a slightly lighter cast.

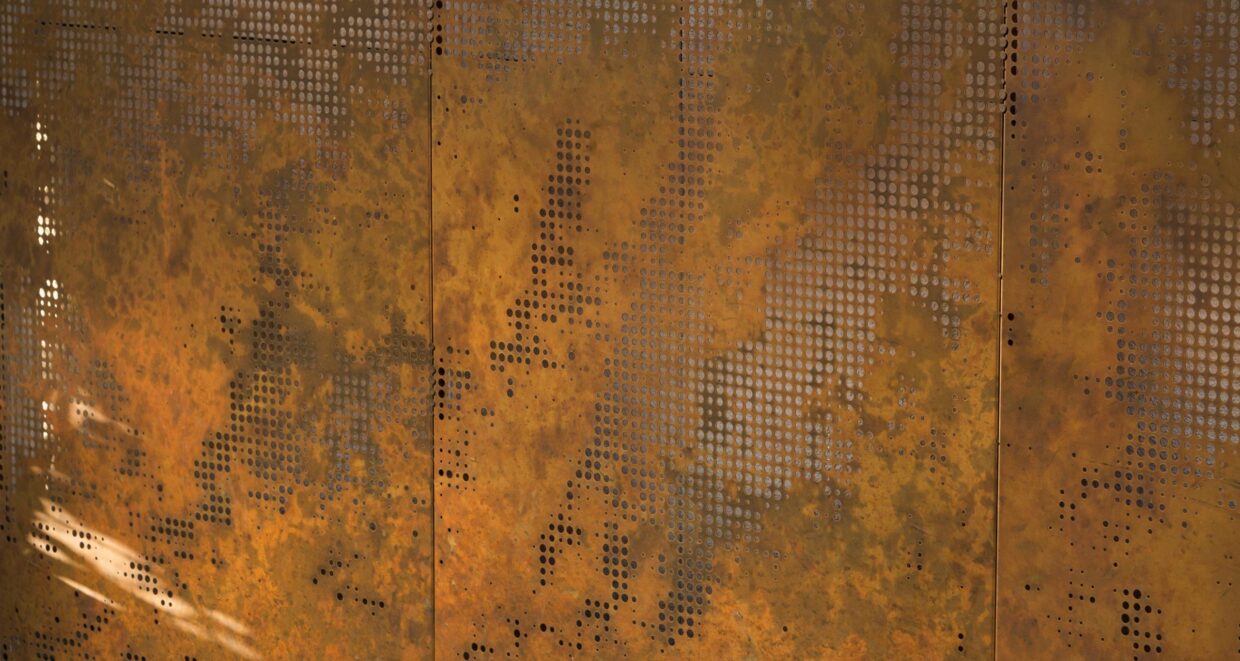

More often, zinc is used in the preweathered form. The preweathered surface is developed at the mill source. The surface arrives with a dull gray to greenish gray coating of zinc carbonate on both sides of the sheet. Zinc sheet is also available in black and gray-black colors. The colors are developed by oxidation processes and are successfully used in exterior applications. These flat, dark colors have very low reflective levels. They absorb heat like all black metals, so caution should be exercised when used where they are accessible to touching.

Other colors are possible on zinc as well. Zinc is a reactive metal and accepts influences of chemical oxidation processes on the surfaces. Whites, pale yellows, and various tones of gray can be developed on zinc surfaces. The development of various patination colors on zinc are in their infancy as far as the architectural and ornamental industry.

In the United States, zinc has experienced heavy competition from other gray-colored metals, such as lead-coated copper and terne-coated stainless. With growing concern for the environmental hazards posed by lead, its producers should be able to capitalize on the nontoxic nature of this metal. Runoff from zinc poses no hazard to the surrounding environment. Zinc and its natural oxides are nontoxic to human and plant life and can be handled without health risks.

“Zinc fever” is a major hazard, however, when the vapors of zinc oxide are produced and inhaled during welding or brazing operations. This illness is characterized by headache, chills, fever, and nausea and can be quite debilitating. The symptoms may be delayed 4 to 12 hours after exposure. Symptoms disappear upon intake of fresh air and rest. The illness usually lasts from 24 to 48 hours. Perform welding and soldering operations only in well-ventilated areas, with the use of respirator equipment. Cutting with plasma torches will also produce zinc oxide fumes. Avoid performing this operation in confined spaces. Use a respirator.

Zinc is used in many ointments and lotions for protecting and treating topical ailments of the human body. Another name for the zinc oxide ore is calamine. The bug bite and poison ivy lotion with the same name contains zinc as an itch inhibitor. Zinc sulfate is used as an aspirant ingredient in many antiperspirants.

Zinc is recyclable. Of zinc ingot, 5% to 10%%, is derived from recycled metal. This percentage should increase with time as more of the metal is recovered and recycled. Current scrap value of the metal is low. The metal’s dull gray color makes it difficult to identify and distinguish from other scrap metals. As the value of scrap increases, the identification and separation of zinc from other metals will improve and so will recycling. Zinc refinement and casting processes use less energy than refining and casting operations for aluminum and copper. The low melting point of the metal will keep the recycling costs down in comparison with most other metals. Zinc uses lower amounts of energy during production and processing and produces less pollution than copper production.

*Although we do not offer supply only sheets for unpatinated zinc, we are happy to custom fabricate based upon your project’s needs. We selectively partner with vendors offering the highest quality materials available in many sizes and thicknesses. Please call for details.