Get Inspiration, Delivered.

Join our newsletter and get inspiring projects, educational resources, and other cool metal stuff, straight to your inbox.

One of the more overlooked and underrated decisions in today’s AEC space—and one that can have some of the most lasting consequences—is how a building’s metal surfaces are finished.

Design and construction teams want to balance aesthetics, durability, budget, and sustainability. Between rising labor costs and increased costs of goods, the stakes are high. However, when it comes to choosing between a natural patina and a painted or coated finish, the decision isn’t just about color or cost; it’s also about how the material will be used and will weather over the decades.

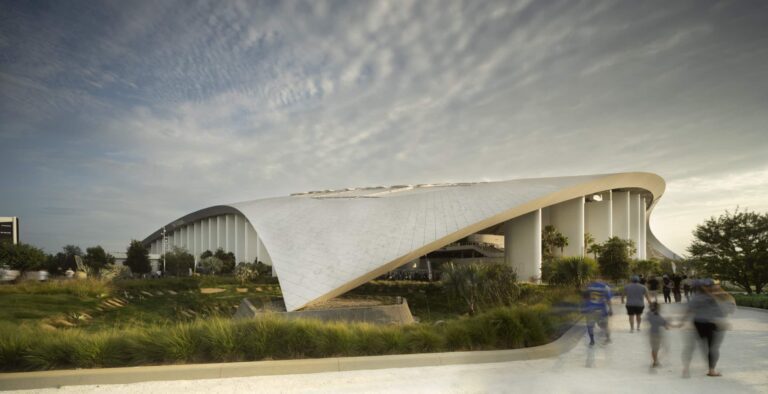

PHOTO © A. ZAHNER COMPANY.

So, what are the trade-offs, and what do you need to know to make the best decision for your design or project? And how can design teams cut through the confusion to specify finishes that stand the test of time?

Here are some big picture questions to begin with when exploring the differences among finishes on architectural metals, including faux patinas, coatings, and natural patinas:

- What is the desired base metal to be used?

- Is the finish a natural oxidation on the surface of the metal or is it an artificial coating?

- Will the finish continue to oxidize as it is exposed to the atmosphere?

- How long will the finish last before the material will need to be replaced or considerable maintenance be applied?

The Debate of Paint vs. Patina: Why It Matters More Than Ever

At first glance, paints, coatings, and patinas might seem interchangeable—they can all provide color, character, and surface protection. But there are critical differences you should consider.

Paints and coatings offer predictability. They can match a Pantone color, cover blemishes, and create a uniform appearance across a surface.

So, what is a patina? Merriam-Webster offers several definitions of “patina,” but the one we care about is this:

“A surface appearance of something grown beautiful, especially with age or use.”

Patinas are the result of natural, chemical, and environmental reactions. They form naturally on metals like copper, zinc, and weathering steel as they oxidize and interact with the atmosphere. Zahner has developed proprietary methods to accelerate and guide this process, creating authentic, living finishes that are truly one-of-a-kind.

As climate and context become increasingly central to architectural narratives, more architects are seeking materials that express change, time, and place without having to wait for it to occur over a long time frame and without being dependent on climate and weather.

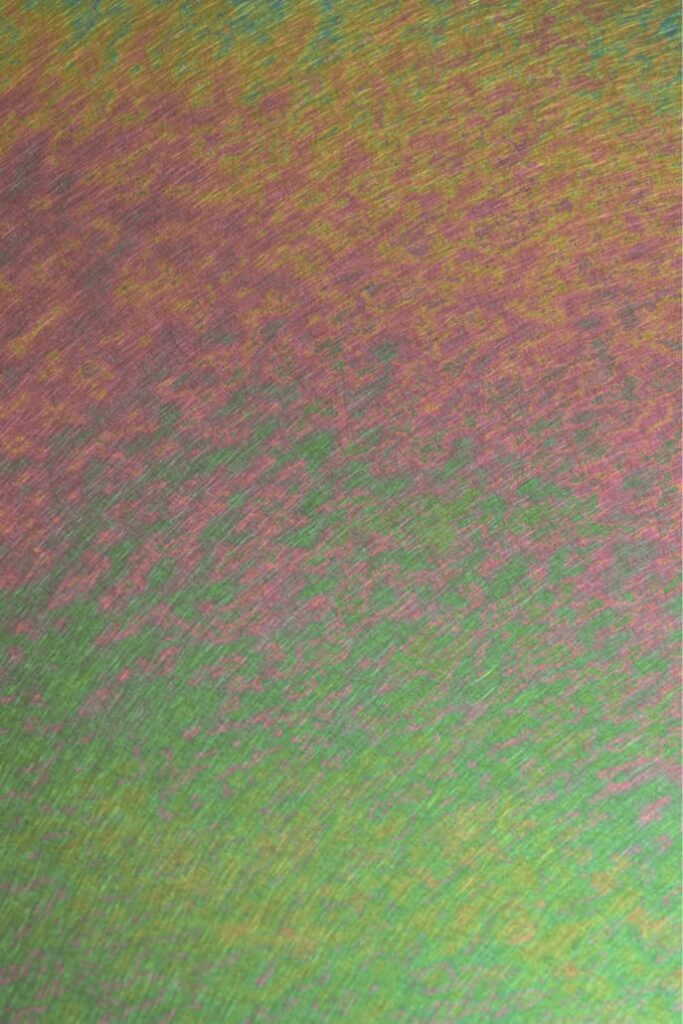

PHOTO © A. ZAHNER COMPANY.

What to Know About Paint and Coating Limitations

Paints and coatings can offer initial uniformity; however, there are trade-offs:

- Material Confusion: Faux patina finishes being called “patinas” can cause confusion about what material and building characteristics are being considered. Aluminum is the most common material for paints and coatings, while copper, steel, and zinc are the best choices for natural patinas.

- Aesthetic Limitations: Coatings often attempt to mimic natural materials, such as wood grains, rusted steel, and verdigris copper, but lack the depth, variation, and naturally protective/healing characteristics of their patinated counterparts. These coatings can look static, sterile, dated, or artificial.

- Maintenance and Longevity: Paints and coatings can fade, chip, or peel prematurely, especially in harsh climates, and often require repainting or refinishing over time.

- Cost Confusion: Ironically, faux patina finishes can be more expensive than natural materials, particularly when labor-intensive painting processes are used to simulate oxidation effects.

- Environmental Concerns: Many coatings contain volatile organic compounds, require high energy usage, and present disposal challenges. In contrast, natural patinas use fewer synthetic materials and require less upkeep over time.

Faux patina coatings are designed to resemble natural aging, and these products may feature mottling or panel-to-panel variation to simulate oxidation; however, they don’t age, evolve, or deepen in the same way natural patinas do. Since most of these are not high-performance coatings, they tend to fade, chip, or peel after a relatively short period.

What Owners, Architects, and Designers Want

Whether it’s a civic landmark, cultural center, or boutique hotel, project teams want more than a finish; they want a story that fits the time, place, and context of the project. They want materials that:

- Age gracefully: Surfaces that change in response to sun, rain, and pollution can reinforce a building’s connection to its environment.

- Are genuine: There’s a renewed desire for authenticity—real metals with authentic patinas provide surfaces full of character, natural variation, and lasting complexity.

- Perform reliably: A beautiful facade that flakes in five years is no bargain. Patinas transform the metal’s surface itself, not coat it. The result is a lasting and self-protecting finish that resists flaking, peeling, and other common coating failures.

- Require little maintenance: Zahner patinas naturally take care of themselves through self-healing oxidation.

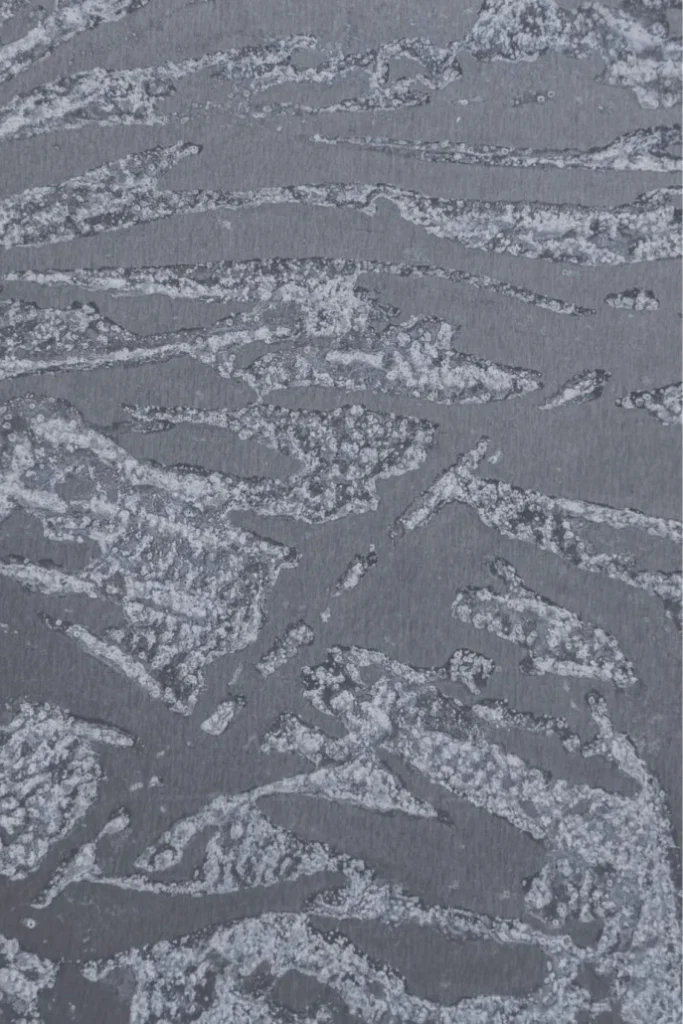

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

What Artisanal Patinas Brings to the Table

The right finish should be expressive, enduring, and grounded in the material. Authentic patinas offer lasting integrity with real character.

For more than 125 years, Zahner has worked with architectural metals to develop finishes that are as durable as they are distinctive.

Zahner surfaces are the result of safe and sustainable chemical and environmental processes that involve pre-oxidation under controlled conditions for optimal performance. These are not coatings layered on top. They are elemental transformations that begin with the base metal itself.

Each signature patina, such as Dirty Penny Copper, Star Blue Copper, and Solanum Weathering Steel develops its color and character from the inside out. They’re designed to evolve with the building, gaining character over time, yet remain nuanced in color and reflectivity.

Consider the Hunter Museum of American Art in Chattanooga. Initially envisioned with limestone cladding, the design team pivoted to Zahner’s Hunter Zinc to achieve a similar look with less weight, lower material and installation costs, and lowered costs for multiple trades on the project. The result was a soft, organic facade that quietly transformed the museum’s identity and saved the client millions.

Materials, colors, patinas, and other surface coatings are essential design details. And they deserve careful forethought and planning.

Paint and other color coatings have their place, but when the goal is timeless beauty, lasting performance, and authentic storytelling, patina offers something more. In an era of increasing scrutiny regarding materials, budgets, and environmental impact, the most intelligent surfaces are those that improve with age.

Want to explore the difference for yourself? Check out Zahner’s entire Materials Collection or request a sample today. And if you’d like to use one of our natural patina offerings, we can also recommend one of our Versatile Systems offerings and provide details, specifications, and recommendations for panel sizes and installation to accommodate your vision.