The Zahner Engineered Profile Panel System (ZEPPS) provides artists and designers with the capability to create any sculptural form. The system is developed by the Zahner engineering and manufacturing team, and is frequently used to create unique building shapes, sculpture, custom canopies.

When used in architecture, ZEPPS forms can be developed to contain a complete wall system. This can include the exterior skin, waterproofing membrane, vapor barrier, structure, MEP, insulation, and interior wall substrate. By offering this as a complete system, designers can confidently develop curving architecture without worrying about how other trades will integrate into a unique curvilinear system.

It works a little bit like a model-airplane kit. Zahner’s computer system will go through the design automatically and organize all the parts to create a shape. The cutting patterns get sent over to a computer system that cuts the shapes. All the shapes come in a box numbered, and as long as they fit the numbered parts in the right places there’s very little measuring. You get a unique prefabricated shape that comes in a box.

— George Metzger, Principal at Adamson

The Zahner team inspects progress on installation of the Angel Hair eyebrows.

Photo © A. Zahner Company.

Modular construction facilitated efficient installation of the eyebrows.

Photo © A. Zahner Company.

Benefits and Features of ZEPPS

Working within the ZEPPS framework provides a number of benefits — for both the design team developing the design as well as the general contractor and client’s budgetary needs.

- Custom Prefab: All parts are prefabricated as shippable assemblies up to 40′ long

- Rapid Installation: Each ZEPPS assembly can be installed easily and quickly in the field

- Minimal Connections: Assemblies require only a few connections to the structure

- Parametrically Derived: Zahner engineers can work from the designer’s 3D model in any file format, as well as from a digitally scanned physical model

- Any Material: Any surface material can be applied to create the finish surface, various thin metal skins, terra cotta, slumped glass, acrylic and fiberglass

- Any Form: Complex curves, non-euclidian geometries, fractured surface geometries

- Reduced Structure: ZEPPS provides a secondary structure. It is a structural, pre-engineered framing panel system

- Reduced Schedule: Using ZEPPS to develop a curved building form versus stick-building will typically reduce a project by three months

ZEPPS: Modular Manufacturing

ZEPPS provides a modular custom prefabricated product. As such, the physical parts are entirely derived from digitally defined geometries. Zahner engineers translate these surface geometries into parametric parts. When assembled, the large panel elements interlock and make up a continuous surface. There is no other system quite like it.

The parametric relationships take in the necessary strength of the individual components that make up the finish panel. Connections back to the main structure are clearly defined and minimized for ease and speed of installation.

As a modular surfacing system, the vapor, water and thermal barriers can be incorporated into the panels. Allowances for sprinkler, and MEP systems can be incorporated into the systems by including them in the parametric defined surface.

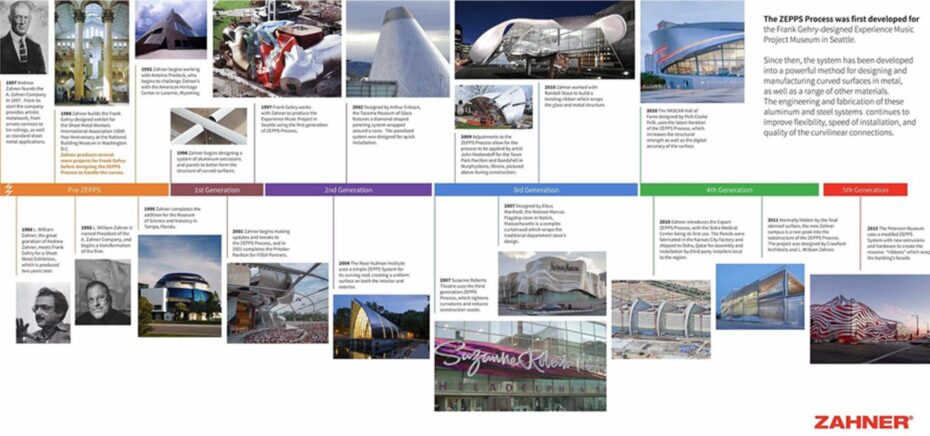

History & Timeline of ZEPPS

ZEPPS was first developed to provide a methodology for manufacturing non-Euclidian curved forms in architecture.

Zahner has been producing unique and decorative architecture since the company’s founding in 1897. ZEPPS stands for Zahner Engineered Profile Panel System, and was developed to enable architects to design and build imaginative forms with ease. The Antoine Predock-designed Museum of Science and Industry was the impetus which led to the research and development for the system. The first iteration of ZEPPS was used during Frank Gehry’s Experience Music Project, in Seattle, Washington.

To learn more about manufacturing curving forms for art and architecture contact the Zahner sales team.