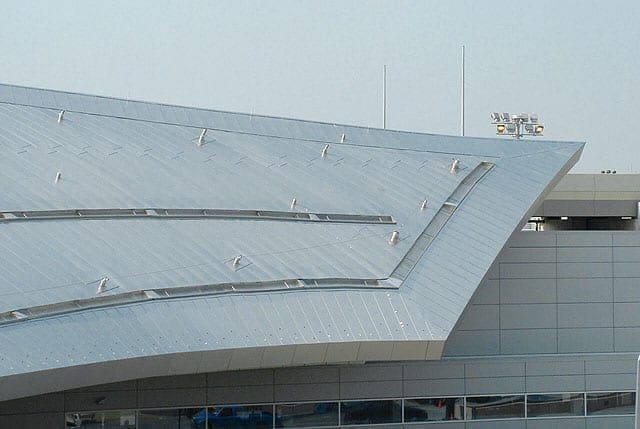

Dallas Fort Worth Airport, Terminal D

The new Terminal D at the Dallas Fort Worth Airport is the largest square-foot project completed to date using Zahner’s Inverted Seam roof and facade system. The new terminal was built to give international travelers a lasting positive impression of their arrival and departure from the United States.

The building envelope for this work includes approximately 500,000 square feet of surface covered with 11 acres of stainless steel cladding for the roof. Just over two miles of gutter and five miles of fascia panels adorn the roof. The entirety of the building envelope metal system was included in the scope for the Zahner team. Zahner worked with the architects at HNTB, Corgan Associates, and HKS, to complete this vast project.

Photo courtesy Bing Maps.

Energy Efficiency

The Zahner Inverted Seam roof is part of the total low-energy solution for the project, reducing the cooling costs by more than 90 percent during peak electrical demand hours. The Terminal D development program includes design of the airport’s central thermal storage tank, a structure that utilizes less expensive electricity at night to create a store of ice to cool the terminal during daytime hours when rates are higher. The project was reviewed by the Clean Airport Initiative team of experts to evaluate incorporated features of sustainable design and to use it as a case study for upcoming guidelines for sustainable airport design.

Photograph by Justin Cozart.

Photo A. Zahner Company.