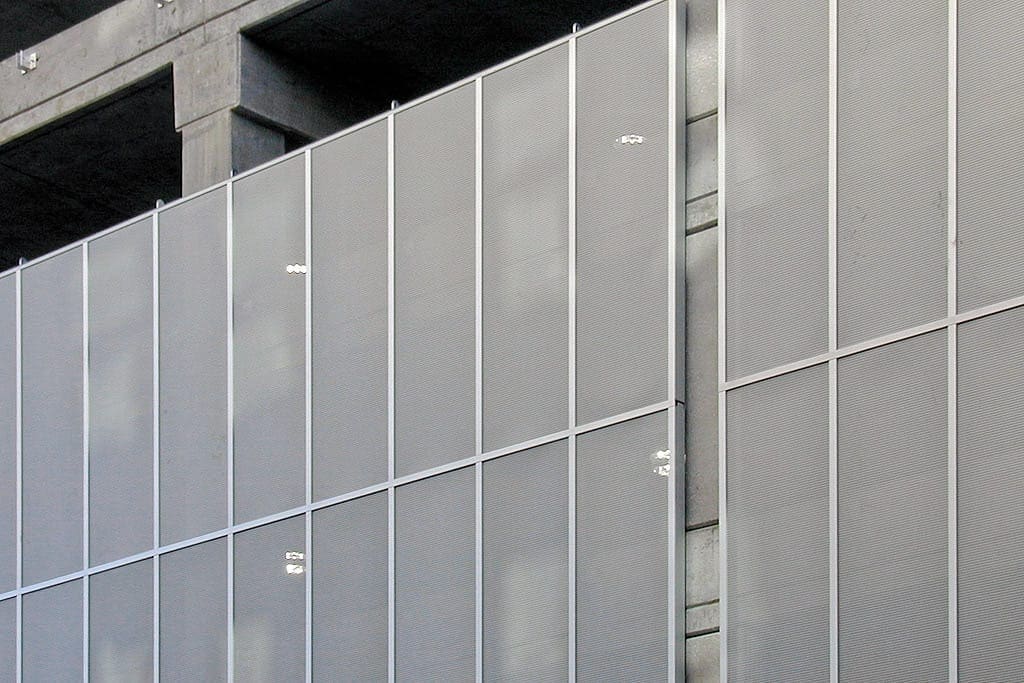

Standard Parking Garage at 11th & Oak

Designed by George Butler Architects for the Power & Light District of Downtown Kansas City, this is a parking structure’s facade was constructed using stainless steel as well as perforated aluminum surface to allow airflow for an otherwise congested space.

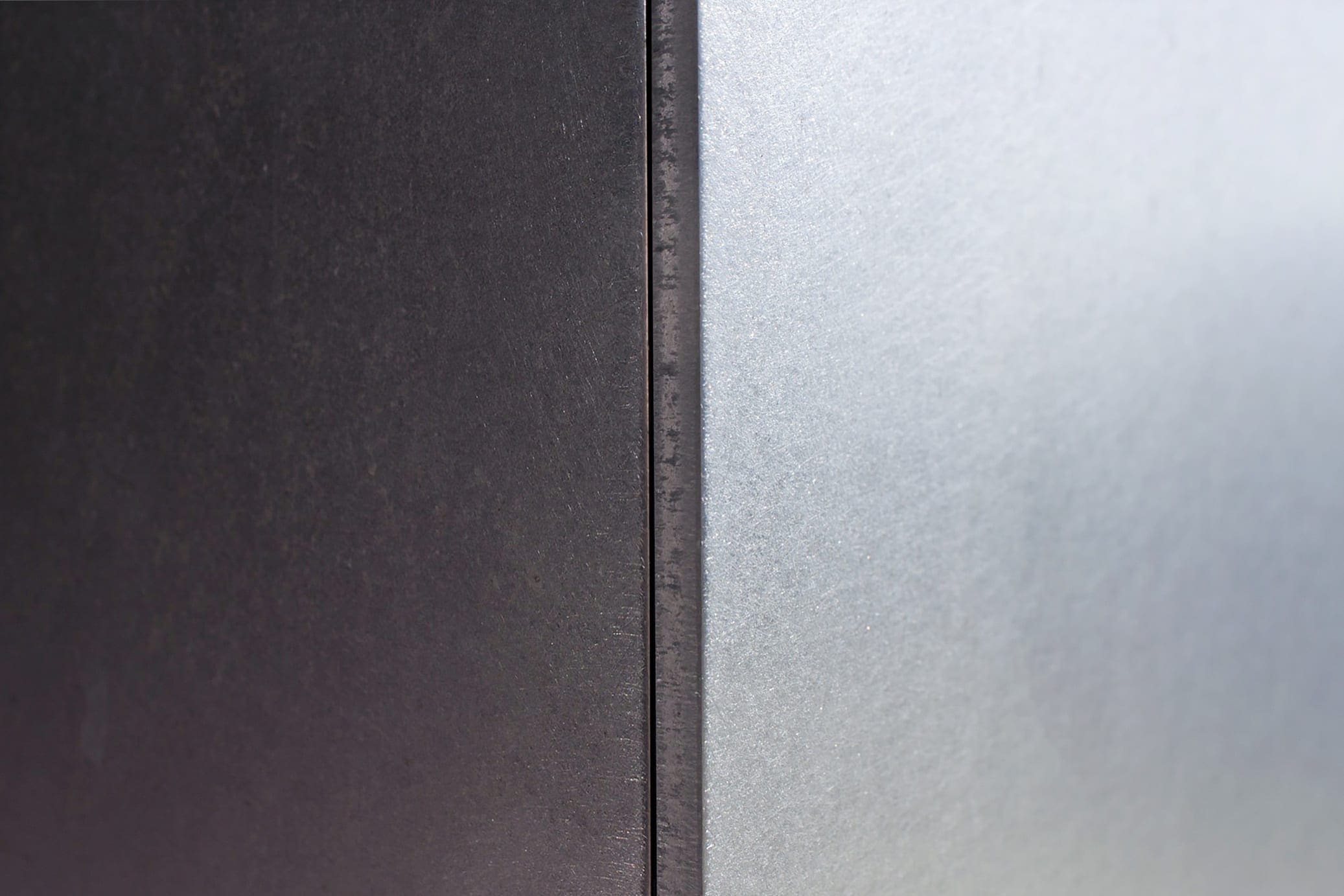

The aluminum screen wall was engineered, custom perforated, and installed as an facade panel system. The system also has uses for unusual panel sizes and unique details, as was the case with Standard Parking. Each of the panels was installed using an the Inverted Seam dry-joint system for integrated walls. The cornice and bold stainless steel fins were engineered, fabricated and installed to digitally defined coordinates.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Photo © A. Zahner Company.

Building the Standard Parking Garage

Zahner developed the design for Standard Parking Garage using drop and lock details to enable quick and simple installation. Each of the panels locks into anchored connections on the concrete structure. This enabled a rapid schedule for the project’s facade.

The above photographs were more than a decade after the project’s completion. Stainless steel is often chosen over aluminum due to its high-performance sheen which never dulls and requires no maintenance. Aluminum is more porous, and over time it begins to dull, but this is not yet the case with Standard Parking Garage screen-wall.