Kansas City Star

Kansas City Star Production Facility

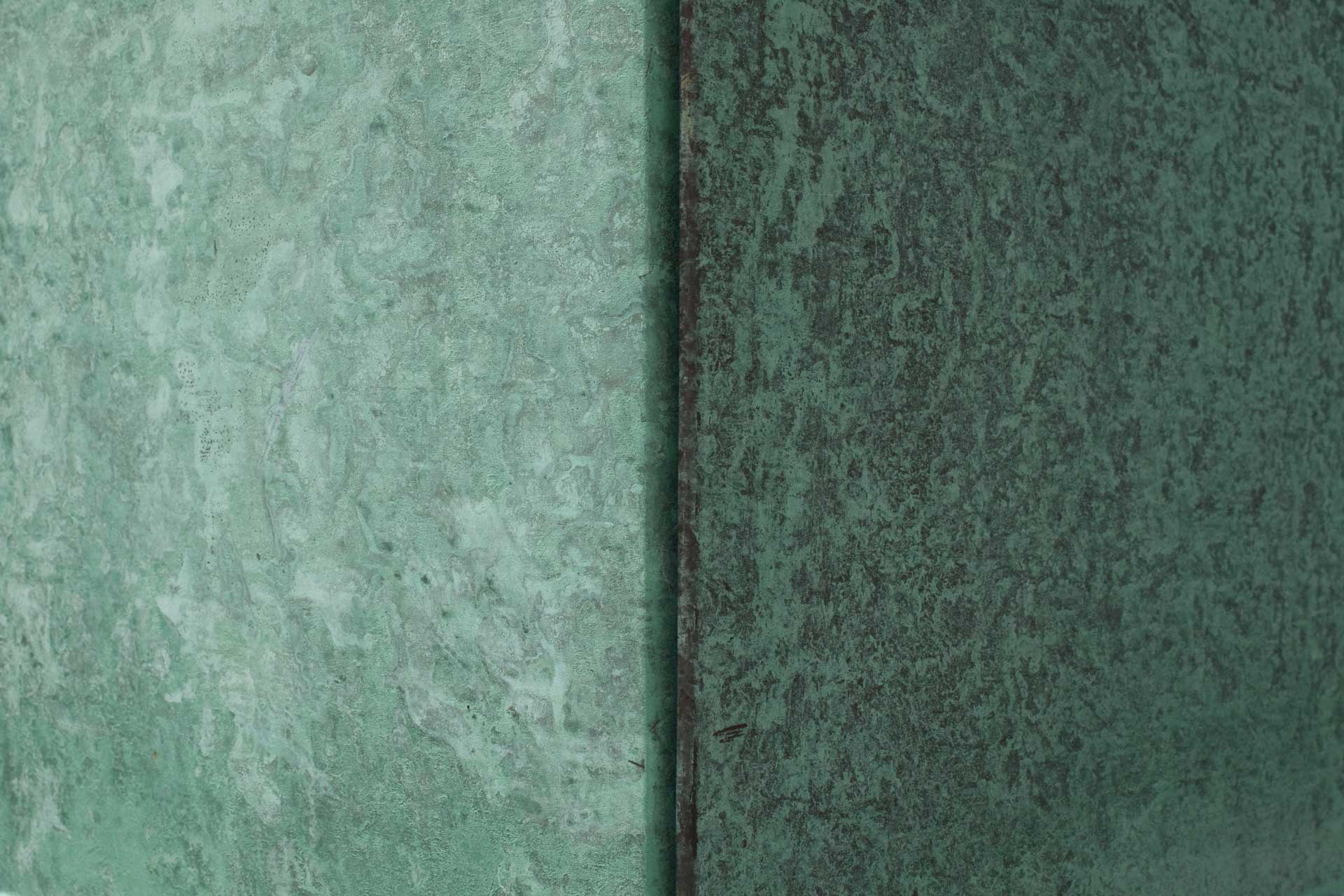

The production facility for the Kansas City Star includes a locally manufactured, custom-patinated copper, created by Zahner for the building’s facade. The new production facility for the Kansas City Star was designed and developed by The Austin Company, an engineering design firm specializing in large-scale industrial facilities.

Zahner developed a preweathered copper patination system for this building. An estimated 4155 pre-patina copper panels were installed on the building’s surface to create the 80,000 SF surface area. The building’s green surface is mottled and variegated, a patina designed to age the building’s copper surface by 200 years. The natural patina will continue to grow and change in appearance as it ages. The patina provides a layer of natural protection for the copper alloy.

The Kansas City Star Production Facility.

PHOTO © A. ZAHNER COMPANY.

The Kansas City Star Production Facility.

PHOTO © A. ZAHNER COMPANY.

The Kansas City Star Production Facility.

PHOTO © A. ZAHNER COMPANY.

The Kansas City Star Production Facility.

PHOTO © A. ZAHNER COMPANY.

The Kansas City Star Production Facility.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.