The Petersen

The Petersen Automotive Museum in Los Angeles, California:

Situated on Los Angeles’ famous Miracle Mile, the newly renovated Petersen Automotive Museum has achieved an iconic status while creating open spaces which invite community engagement. The design encases the building in a red-painted corrugated aluminum rainscreen system which acts as the backdrop for a series of stainless steel structural ribbons. These scopes were engineered, manufactured, and installed by Zahner.

Designed by Kohn Pedersen Fox (KPF) in New York with the construction management by Matt Construction in Los Angeles, Zahner was brought onto the project early on in the planning and development process. Starting under a Zahner Assist (Design Assist) contract, the construction team developed a fabrication and installation strategy with the engineers at Zahner.

This is the second project completed by Zahner with KPF. The two teams worked together prior on the IBM Headquarters in Armonk, New York.

PETERSEN AUTOMOTIVE MUSEUM IN LOS ANGELES, CALIFORNIA.

PHOTO © A. ZAHNER COMPANY.

Making the Petersen Automotive Museum

Design development for the Petersen Automotive Museum began in 2012. Principal Trent Tesch knew that the complex shapes would be best defined under a Design Assist contract with Zahner. Examining the forms gave the team an opportunity to approach their design with as much information as possible. Zahner Assist enabled KPF to bring the client into a conversation with Zahner.

Sharing models and preliminary drawings while the design was still conceptual allowed for conversations regarding costs and aesthetics to remain transparent, assisting the client during the decision making process.

The project made use of several Zahner technologies and methodologies: the ZEPPS Process for designing and manufacturing the building’s curved forms; the Angel Hair non-directional surfacing applied to each of the stainless steel skins attached to the curved forms; and Zahner Assist, Zahner’s method for developing complex projects into factory-produced realities. The project also includes an ImageWall custom perforated metal screen which continues the architect’s design, mimicking the stainless ribbons in a perforated metal graphic across the building’s parking structure. The Petersen Automotive Museum is the direct result of a design team confidently departing from convention.

PERFORATED METAL SCREENWALL BY ZAHNER CONTINUES THE PETERSEN AUTOMOTIVE MUSEUM’S SCULPTURAL MOTIF.

PHOTO © A. ZAHNER COMPANY.

UNDERNEATH THE UNDULATING RIBBON FACADE OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

A PERFORATED PARKING GARAGE FACADE CONTINUES THE STAINLESS STEEL RIBBON MOTIF.

PHOTO © A. ZAHNER COMPANY.

DETAIL OF THE FACADE OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

PETERSEN AUTOMOTIVE MUSEUM

PHOTO © A. ZAHNER COMPANY.

Design Assist Mockup for the Petersen Automotive Museum.

Photo © A. Zahner Company.

Design Assist Mockup at dusk for the Petersen Automotive Museum.

Photo © A. Zahner Company.

The Mock Up as a Design Catalyst

As part of the Zahner Assist contract, we included a to-scale visual mockup. Mockups are included as part of this process in order to aid in design decision making and determine the best method for building any given form. The team selected the lower northeast corner of the building’s design to fabricate as a mockup section. This empowered the design team to determine how the ribbons would wrap around the corner, an integral aspect of the building’s design.

The mockup process provided Zahner crucial insight into how to best develop the red-painted structural steel armatures which are used throughout the project. The mockup also helped the design team establish the ideal color for the painted corrugated aluminum surface.

Zahner installers hang a ZEPPS Ribbon Assembly at the Petersen Automotive Museum.

Photo © A. Zahner Company.

Zahner fabricators create the ZEPPS Ribbon assemblies for the Petersen Automotive Museum.

Photo © A. Zahner Company.

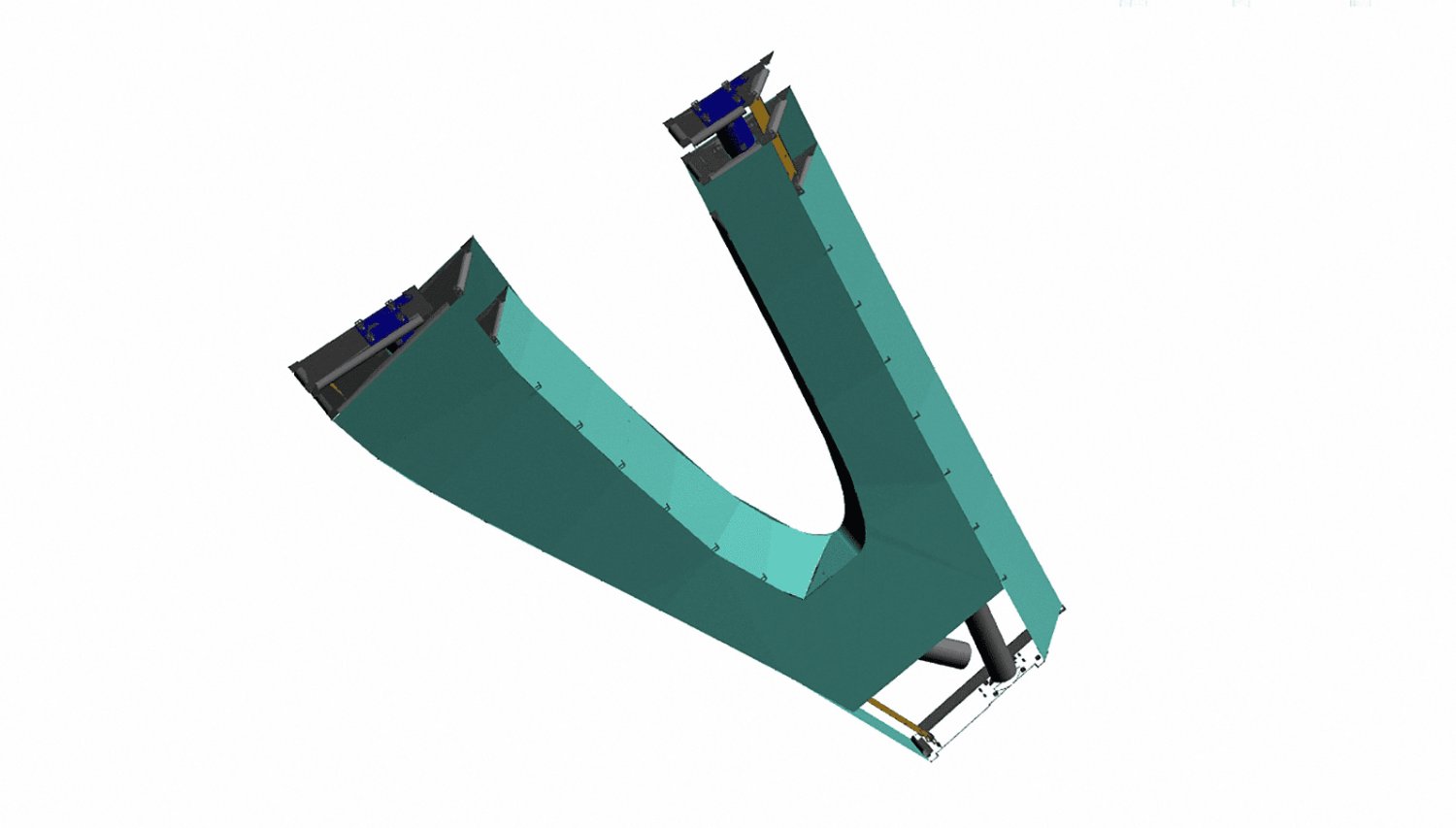

3D Model of a single ZEPPS Assembly for the Petersen Automotive Museum.

Photo © A. Zahner Company.

Zahner field installers at the construction site for the Petersen Automotive Museum.

Photo © A. Zahner Company.

Creating the new Petersen Automotive Museum facade

The existing building, purchased by the Petersen Automotive Museum in 1994, was rectilinear and fairly straightforward in form. It was originally a department store. Six years after the store closed, museum founder Robert Petersen chose the site to house his automotive museum. Since the Museum is nearly devoid of windows, the site was ideal for safely housing Mr. Petersen’s collection without harmful exposure to sunlight.

Because the existing building contained very little glass and was box-like in form, it acted as a blank canvas for the design team. ZEPPS, the Zahner system for developing sculptural forms, was used to build curving stainless steel ‘ribbons’ which wrap the building, giving it a feeling of rapid motion. The result looks similar to the aerodynamic flow diagrams drawn in wind tunnel tests by automotive designers.

Using ZEPPS to Create Dual-Curving Forms

To build complex dual curving forms with the lightest structural loads, Zahner uses the ZEPPS process. ZEPPS stands for Zahner Engineered Profiled Panel Systems, and comprises Zahner’s approach to building complex, curvilinear forms. The crux of the system is the paring down of a complex design into manageable parts for manufacturing.

Using an architect’s 3D model, Zahner’s engineers examine geometry with a manufacturing mindset. Each curve is analyzed and developed into a series of patented aluminum structural components. These components are pre-assembled at the shop and compose the structural form for each ZEPPS Asssembly. Using aluminum extrusions rather than steel allows for a lighter load on the structure of the façade, and also allows for more economical fabrication methods.

The final step in creating with ZEPPS is to clad it in surface material. For the Petersen Automotive Museum, Zahner’s Angel Hair Stainless Steel surface was selected. After the structure is built, each ZEPPS is clad in the desired metal, and loaded onto a truck for field install. By breaking dual curves into units, ZEPPS creates precision within the manufacturing process, and allows for much quicker field installation.

Detail of the Petersen Automotive Museum’s Angel Hair Stainless steel.

Photo © A. Zahner Co.

PETERSEN AUTOMOTIVE MUSEUM IN LOS ANGELES, CALIFORNIA.

PHOTO © A. ZAHNER COMPANY.

ROOF OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

View of Wilshire Blvd during the construction of the Petersen.

Photo © A. Zahner Company.

SCREENWALL AT THE PETERSEN AUTOMOTIVE MUSEUM IN LOS ANGELES, CALIFORNIA.

PHOTO © A. ZAHNER COMPANY.

UNDERNEATH THE ROOF OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

Structural Steel

A new structural steel exoskeleton was needed to carry the loads from the red corrugated rainscreen as well as the cantilevered stainless steel ribbons which arch over the rooftop to provide shading for a private event space.

Working with the designers’ 3D models, Zahner’s team of engineers developed a series of tree-like forms in structural steel to support the ZEPPS Ribbon assemblies. The structural steel skeleton was inspired by hot rod manifolds to serve the dual purpose of providing aesthetic cohesiveness as well as functional support for cantilevered elements of the design. The structural ‘trees’ support the ribbons that flow over the roof area, as well as the Fairfax Ave ground level ribbons.

The ZEPPS ribbons required custom curved structural steel within each unit. Zahner mapped out each curved radius using the 3D model, allowing for fabrication in the shop to be handled quickly and precisely.

Custom Corrugated Aluminum

Painted aluminum acts as the backdrop for the stainless steel ZEPPS forms, echoing the concept of a sports car in bright red intensity. The aluminum was completely custom, and unlike any standard corrugated pattern. The corrugated profile formed an exact 90 degree angle, versus the typical sine wave that is commonly seen in corrugated metals.

To accommodate for the custom nature of this design element, Zahner formed each of the corrugated panels in house, utilizing a custom die within the press brake.

ImageWall Screenwall for the Petersen Parking Enclosure

As a continuation of the stainless steel ribbons, the design team also selected a painted red aluminum ImageWall for the Museum’s Parking Garage. Using Zahner’s patented technology, ImageWall uses perforated holes to map an image across multiple panels. In this case, the image provides cohesiveness, and ties the parking garage in with the larger facade.

IMAGEWALL SCREENWALL ENCLOSING THE PARKING STRUCTURE OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

DETAIL OF THE SCREENWALL FACADE OF THE PETERSEN AUTOMOTIVE MUSEUM.

PHOTO © A. ZAHNER COMPANY.

PARKING STRUCTURE SCREENWALL AT THE PETERSEN AUTOMOTIVE MUSEUM IN LOS ANGELES, CALIFORNIA.

PHOTO © A. ZAHNER COMPANY.

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.