KCPD Headquarters

Kansas City Police Department HQ RENOVATION & EXPANSION

KCPD Headquarters’ renovation and expansion was led by Helix Architecture and features Zahner fabrication and design assist exploration. The existing building, which hadn’t been renovated since opening in 1938, features both a new tower expansion as well as historical restoration and renovation to the original building interior and exterior spaces.

The Kansas City Police Headquarters renovation marks a shift in how police departments can use architecture to shift perception and engagement in the community. The building update provides a modernized facility for KCPD employees, as well as a first floor community atrium for citizens to engage in the Police Department’s Headquarters.

Zahner’s scope on the project included both interior and exterior cassette panels in pre-weathered zinc. The panel layout positions the zinc skins diagonally skyward, and its unique diamond shape emphasizes the vertical nature of the space, providing the new addition with a sense of fortitude.

Photograph of the KCPD Community room during the opening ceremony for the renovated police headquarters.

PHOTO © A. ZAHNER COMPANY.

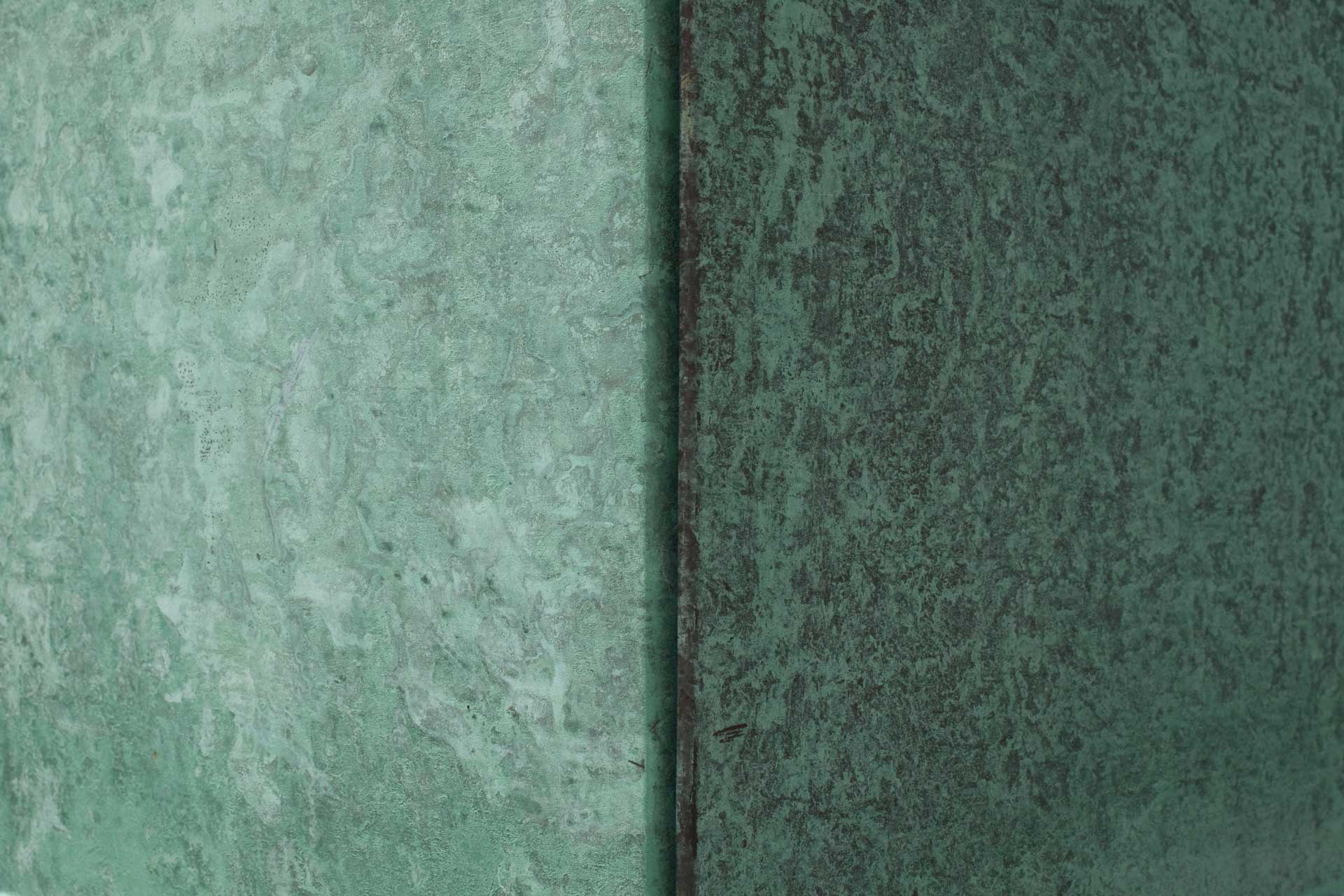

Detail of the punched and custom-embossed zinc exterior facade at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Interior space with custom zinc feature wall at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Interior space with custom zinc featurewall at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Rooftop terrace at Kansas City Police Department Headquarters.

PHOTO © A. ZAHNER COMPANY.

Keeping with the KCPD’s desire to increase community interaction, extensive improvements were also made to the first floor where visitors enter the space. Here a community room serves as a space for meetings and public engagement.

The interior spaces continue the embossed zinc cladding, providing a backdrop for art by Rob Ley of Urbana, and giving cohesion between the addition and the existing historic building. The interior panels also serve the dual purpose of providing noise mitigation at the entrance of the space.

Creating a Custom-Embossed and Perforated Zinc Panel

Rather than adding patina to the sheets, Helix designers were interested exploring various possibilities with machined surfaces. The exterior panels located on the tower expansion feature a racetrack-shaped obround bump which is repeatedly embossed into the metal surface. This texturing of the metal adds rigidity to the panels to prevent wavering in the metal panels. When assembled in unison, the repetition of these shapes emulates the warp and weft of the officers’ cloth uniforms.

The unique panel system was tested in two mockups at Zahner, each of which provided valuable insight into how to provide the complex geometries of the zinc system.

Zinc panel siding mockups are displayed at Zahner for architectural analysis.

PHOTO © A. ZAHNER COMPANY.

Interior zinc wall during installation at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Corner mockup for the KCPD facade.

PHOTO © A. ZAHNER COMPANY.

Rendering of the renovation provided to the KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Designing Custom Perforated Panels using Zinc

The existing entrance for the project is largely composed of non-absorptive materials such as glass and tile. This meant that finding a solution to mitigate noise in the community entrance was of utmost importance. The designers at Helix worked with Zahner to develop a series of micro perforations and sound-absorptive backing on the panels.

The perforations allow noise to enter, while acoustic material nestled within the panel absorbs noise. The perforated surface of the zinc further prevents echo and reverberation of sound from coming back out of the panels. Zahner provided the entire custom perforated panel as one unit, with the acoustic backing already within each panel and ready for installation.

Detail of the punched and custom-embossed zinc panels at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

The building facade has an appearance of armored cladding.

PHOTO © A. ZAHNER COMPANY.

Interior and exterior zinc metalwork at the Kansas City Police Department Headquarters.

PHOTO © A. ZAHNER COMPANY.

Managing the Building’s Historic and Green Construction

In order to accommodate the police department’s need for continued use of the space, the general contractor, JE Dunn, divided the project into several phases. Special consideration was also taken towards historic pieces, such as marble in the restroom. Historically significant materials were refurbished and reused in other areas of the building.

This eco-friendly design decision is also echoed in Helix’s desire to use zinc panels. The zinc was sourced from Jarden Zinc, who also provides coin blanks to mints from around the world (including the blanks used to make the US penny). The leftover material from the coinage is melted down to produce sheets. All zinc used for the KCPD Headquarters is 100% recyclable and environmentally friendly. The project is anticipated to receive a LEED Gold certification.

Interior walls with zinc cladding, photographed with the Rob Ley interior sculpture at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

Detail of the punched and custom-embossed zinc panels at KCPD Headquarters.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

PHOTO © A. ZAHNER COMPANY.

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.