Google Bay View Campus

Google’s Bay View Campus, located at NASA’s Ames Research Center in Mountain View, California, and comprising three buildings, represents a significant milestone as the company’s first self-designed and built campus.

Opened in 2022 and spanning 1.1 million square feet over 42 acres, the campus was brought to life through the collaborative efforts of renowned architectural firms Bjarke Ingels Group (BIG) and Heatherwick Studio.

Grounded in Google’s core themes of innovation, nature, and community, the design prioritizes flexibility. Team spaces are located on the upper level, with gathering areas below, balancing focus and collaboration. Varied floorplates on the second floor create adaptable “neighborhoods” that evolve with team needs. The layout ensures that no employee is more than a two-and-a-half-minute walk from any other, fostering spontaneous interactions and collaboration.

Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick StudioNatural light floods the interiors through clerestory windows with “eyebrow” architectural elements crafted from Zahner’s Angel Hair® Stainless Steel, which add aesthetic appeal while diffusing sunlight to minimize glare.

Aerial view of Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick StudioZahner also provided Design Assist services to ensure constructability, while preserving design intent and considering budget. Zahner collaborated with BIG and Heatherwick designers, as well as general contractor Whiting-Turner, on material selection, fabrication details, engineering, and installation.

The Zahner team inspects progress on installation of the Angel Hair eyebrows.

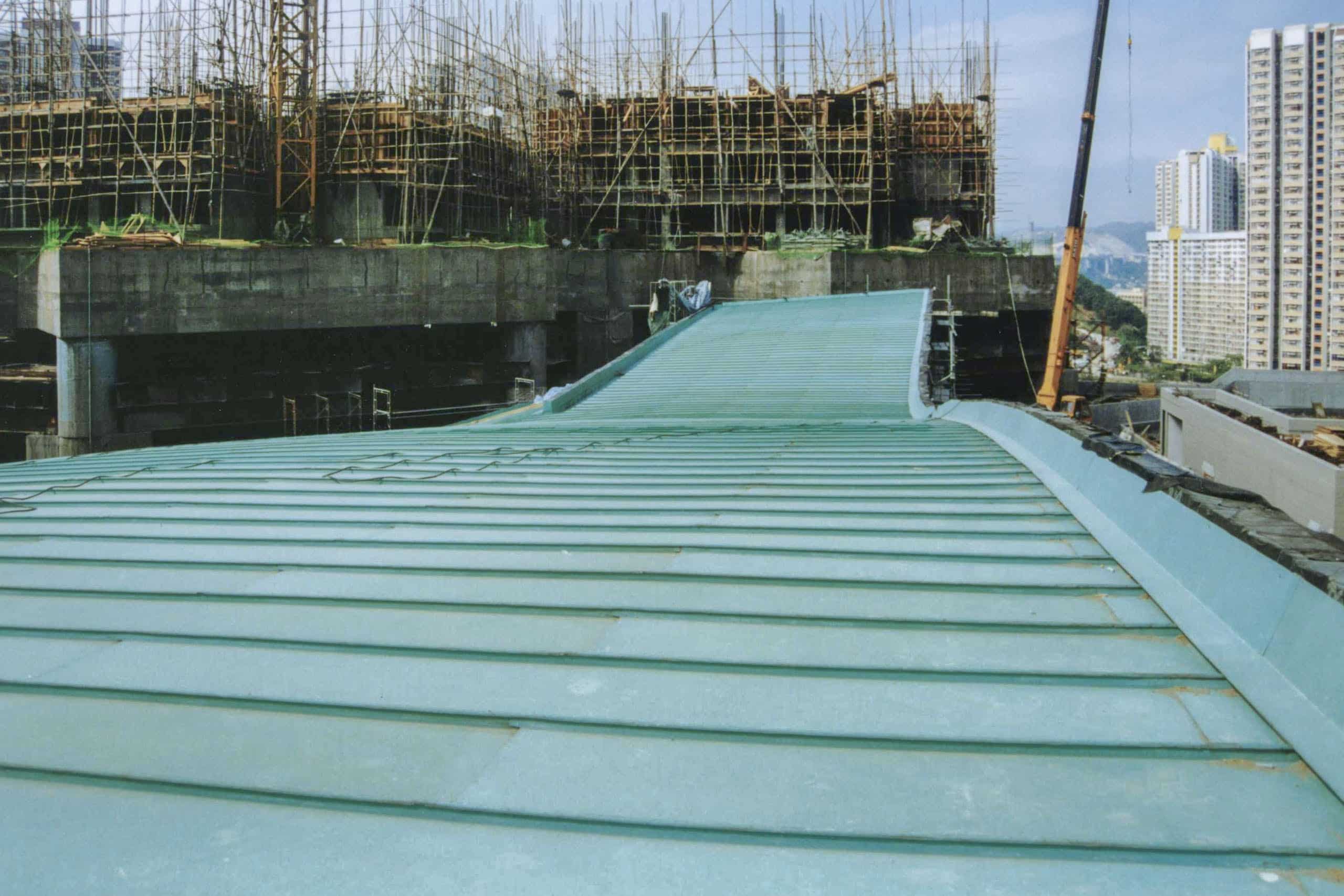

PHOTO © A. ZAHNER COMPANY.Modular construction facilitated efficient installation of the eyebrows.

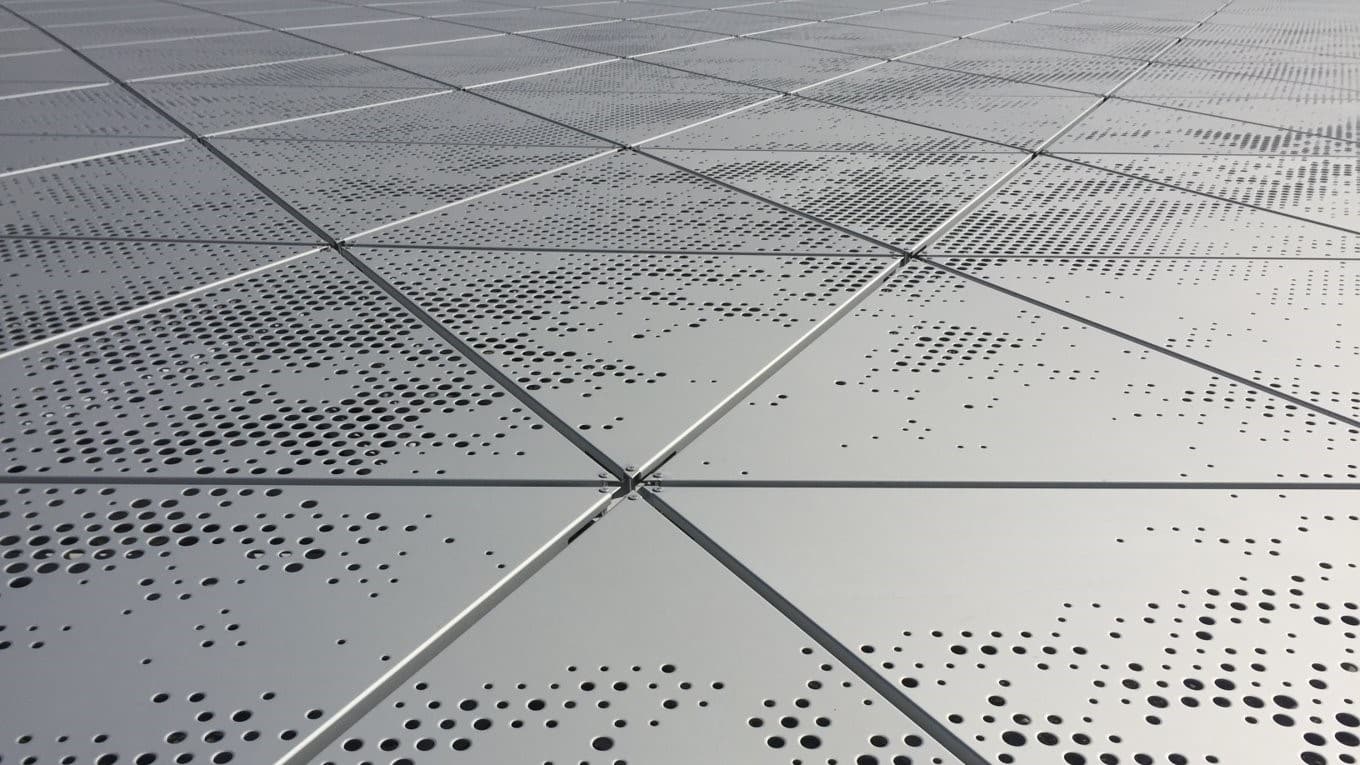

PHOTO © A. ZAHNER COMPANY.Another standout feature of the campus is its distinctive “dragonscale” roof, composed of approximately 50,000 custom-designed solar panels, manufactured by SunStyle. This innovative roofing not only generates nearly seven megawatts of energy but also enhances insulation and reduces thermal heat gain.

Zahner Angel Hair eyebrows and Google's custom-designed dragonscale solar skin roofing.

PHOTO © A. ZAHNER COMPANY.The Zahner team inspecting the Angel Hair eyebrows at Bay View during construction.

PHOTO © A. ZAHNER COMPANY.Zahner Angel Hair eyebrows and Google's custom-designed dragonscale solar skin roofing.

PHOTO © A. ZAHNER COMPANY.The campus is also home to North America’s largest geothermal pile system, which efficiently manages heating and cooling needs, leading to a projected 50% reduction in carbon emissions and saving an estimated five million gallons of water annually. Furthermore, the campus aims to replenish 120% of its water usage by 2030 through on-site recycled water systems.

Aerial view of Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick StudioThe Google Bay View Campus has earned LEED-NC v4 Platinum certification, making it the largest building in the world to hold this certification. It’s also on track to become the largest facility ever to achieve the International Living Future Institute’s Living Building Challenge (LBC) Water Petal Certification.

Panoramic view of Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick StudioGoogle’s Bay View Campus stands as a testament to the company’s vision of integrating cutting-edge design with sustainability and employee-centric spaces, setting a new benchmark for future workplace environments.

Panoramic view of Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick StudioPanoramic view of Google Bay View campus in Mountain View, California.

Photo © Iwan Baan, Courtesy of Heatherwick Studio

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

© Fedora Hat Photography

© Fedora Hat Photography

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.