IwamotoScott

City View Garage, Miami Design District

A geometric display of varying blue-toned aluminum skins adorns the Southeastern facade of the City View Garage in the Miami Design District. Designed by IwamotoScott Architecture, the Zahner-manufactured facade was developed in Kansas City and shipped as nesting parts to the job site in Miami, Florida. Zahner field installers hung the panels.

Sited along the Southern edge of the Miami Design District adjacent to I-195, the parking structure is part of a larger plan to bring arts, luxury, and culture into the new district. The main body of the building is a parking structure above a level of retail storefront and includes a small six story office block.

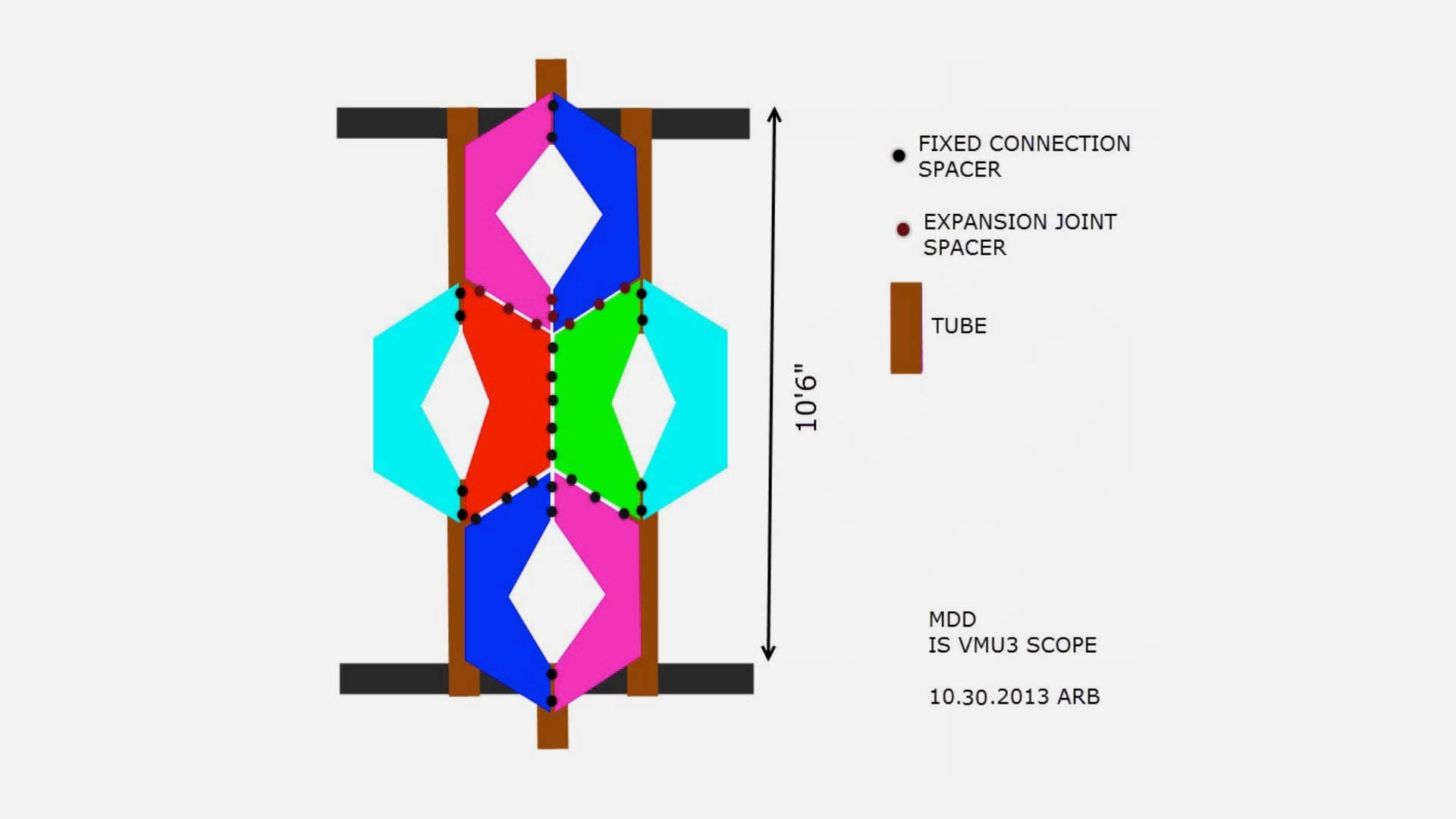

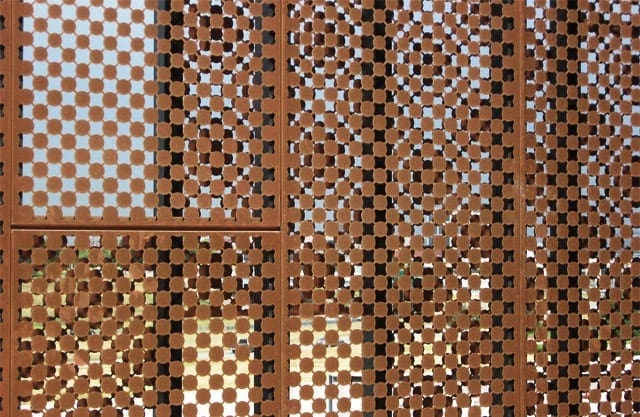

The building’s design averted the need for industrial ventilation of the parking area. IwamotoScott met this challenge with a modular decorative metal screen, whose mechanically-folded aluminum system features variously sized apertures to provide the required porosity for natural ventilation.

IwamotoScott was commissioned alongside New York-based architects Leong Leong and Southern California-based artist John Baldessari, by Dacra and L Real Estate to create three unique facades for the City View Garage in Miami’s Design District. The IwamotoScott portion of the facade wraps around the parking structure’s Southeast corner and includes an elevator lobby, exterior stair, and the office block.

featuring Baldessari's artwork between the Leong Leong Facade and the IwamotoScott facade.

featuring Baldessari's artwork between the Leong Leong Facade and the IwamotoScott facade.Detail of the IwamotoScott Facade for the Miami Design District City View Garage.

Photo © A. Zahner Co.Interior and roof view of the IwamotoScott Facade for the Miami Design District City View Garage.

Photo © A. Zahner Company.Photograph of the IwamotoScott Facade during construction, Miami Design District City View Garage.

PHOTO © A. ZAHNER COMPANY.Developing the IwamotoScott facade for City View Garage

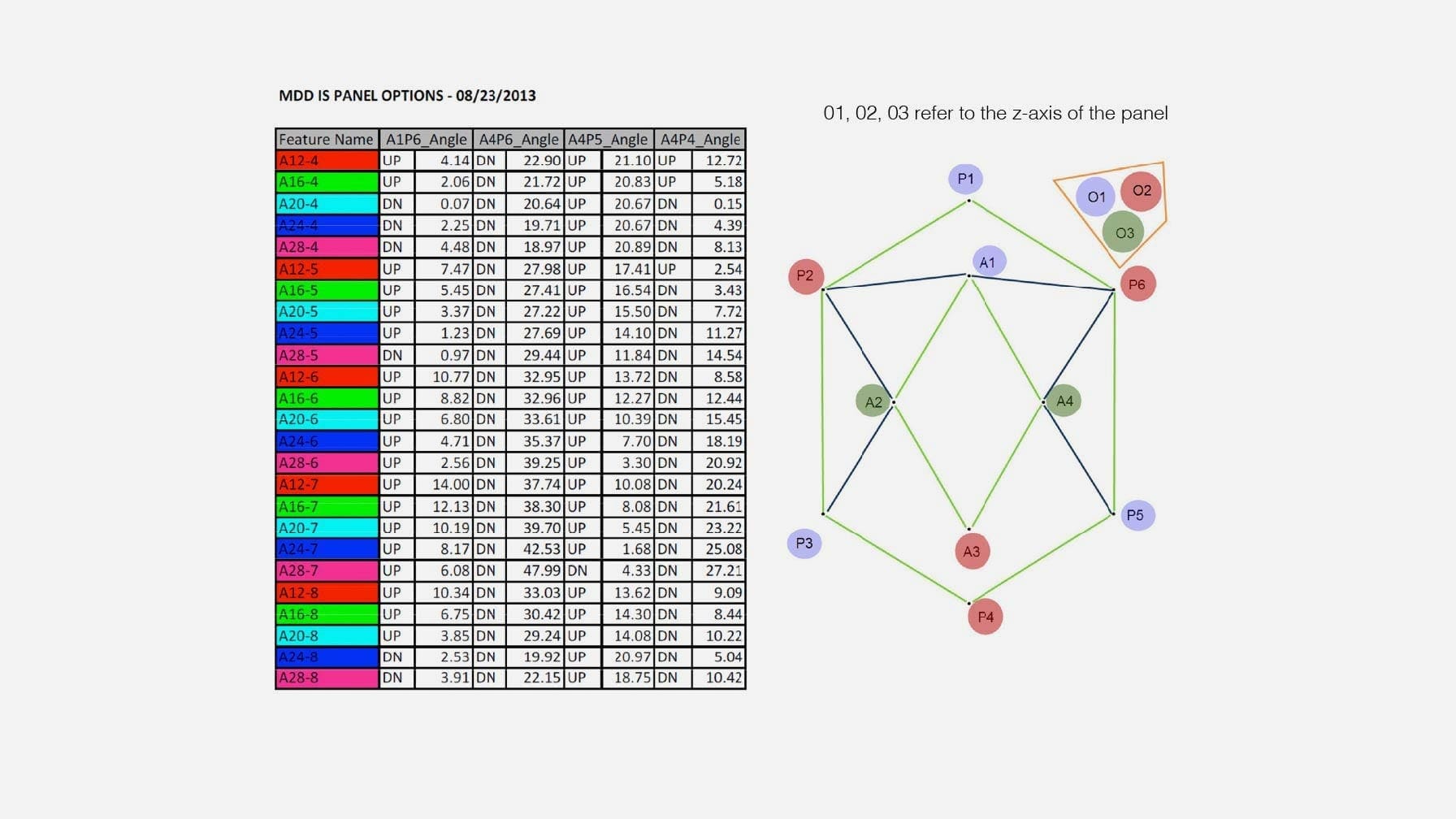

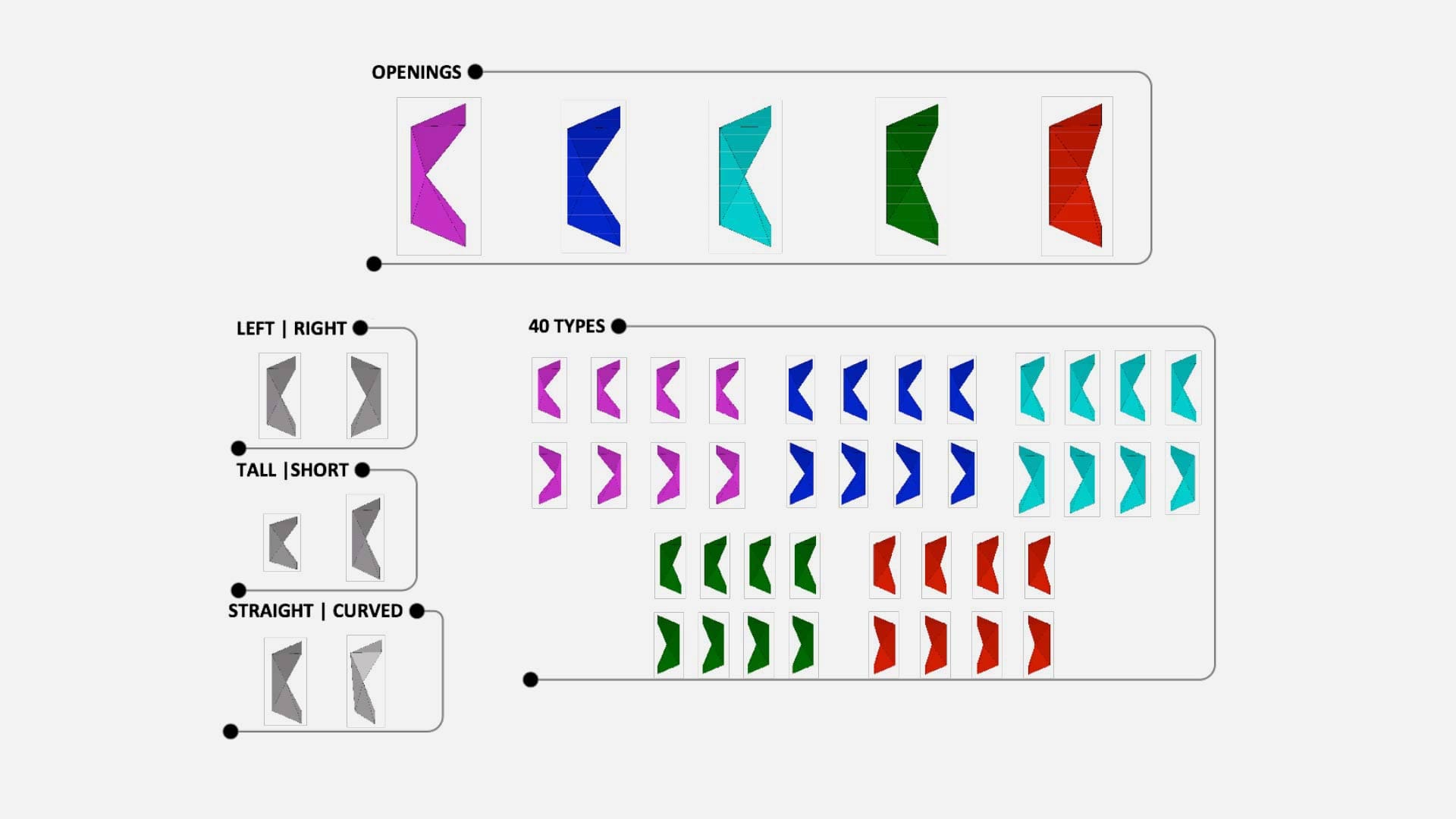

There are five different repeating modules, which are custom-fabricated by Zahner using 40 panel types. Zahner developed the modular design using powercopies to programmatically control the design’s various parts in both the operational engineering, plant, and hanging in the field.

The aluminum parts were painted using a gradient coloring scheme, which provides a subtle gradation of its five unique aperture sizes, suspended from fins which cantilever from the edges of the garage’s concrete slabs.

Digital model of the IwamotoScott facade, color-coded to indicate its five repeating panel types.

IMAGE © A. ZAHNER COMPANY.Diagrams for the IwamotoScott Facade for the Miami Design District City View Garage.

IMAGE © A. ZAHNER COMPANY.Diagram of the 40 panel types used to create the IwamotoScott Facade at Miami Design District.

Images © A. Zahner Company.Nested parts for the IwamotoScott facade in the Zahner Kansas City facility.

Photo © A. Zahner Company.Zahner fabricator crates the aluminum parts for the IwamotoScott Facade.

Photo © A. Zahner Company.Eastern view of the IwamotoScott Facade for the Miami Design District City View Garage.

Photo © A. Zahner Company.Upward view of the IwamotoScott Facade for the Miami Design District City View Garage.

© A. Zahner Company

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.