Neiman Marcus

Neiman Marcus Flagship Store by Elkus Manfredi

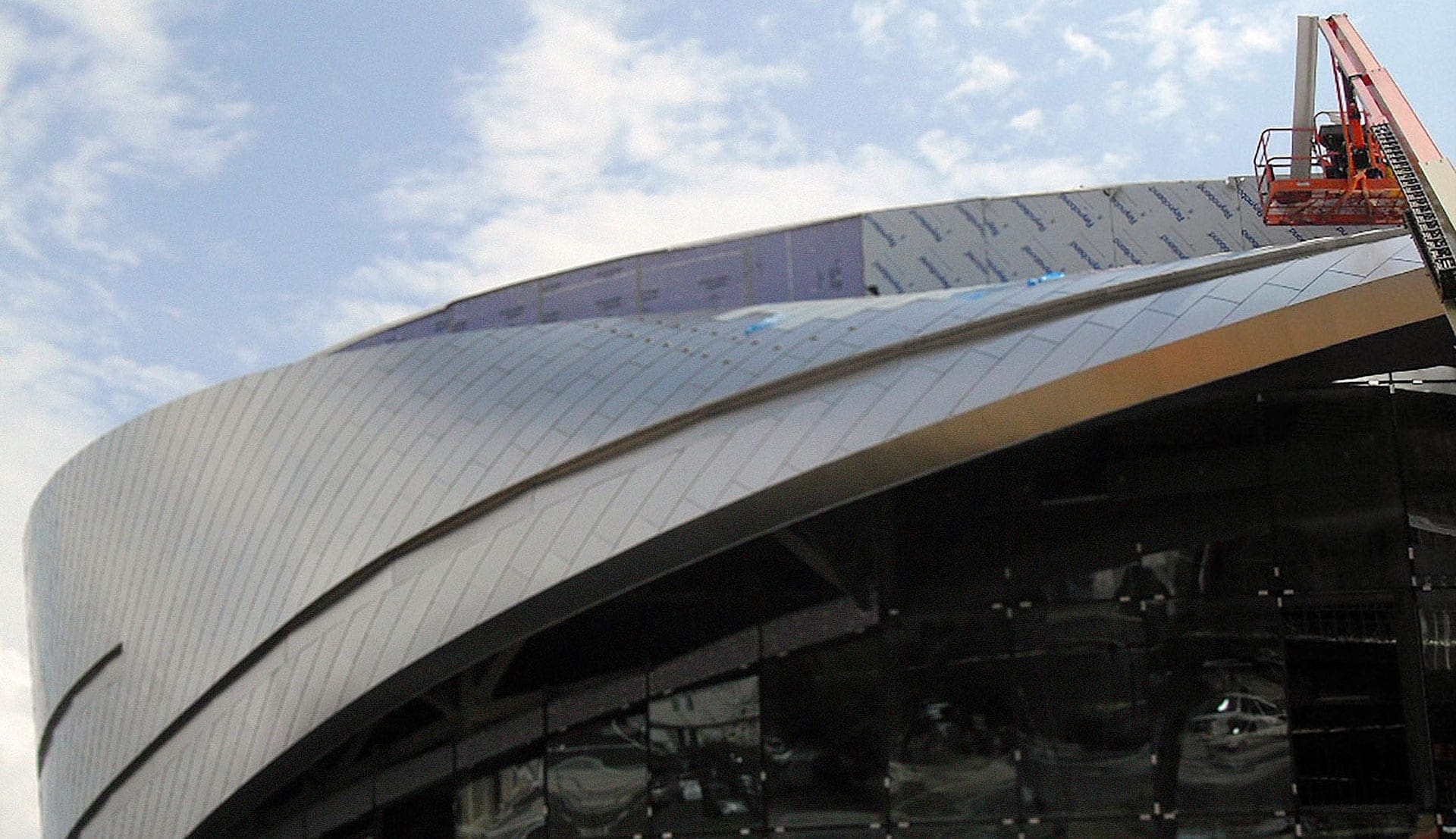

The Neiman Marcus in Natick, Massachusetts is the store’s Flagship property featuring a billowing facade designed by Elkus Manfredi Architects in Boston. The entire surface of the building is wrapped in a stainless steel curtain, a feature which flows throughout and into the building in the same style.

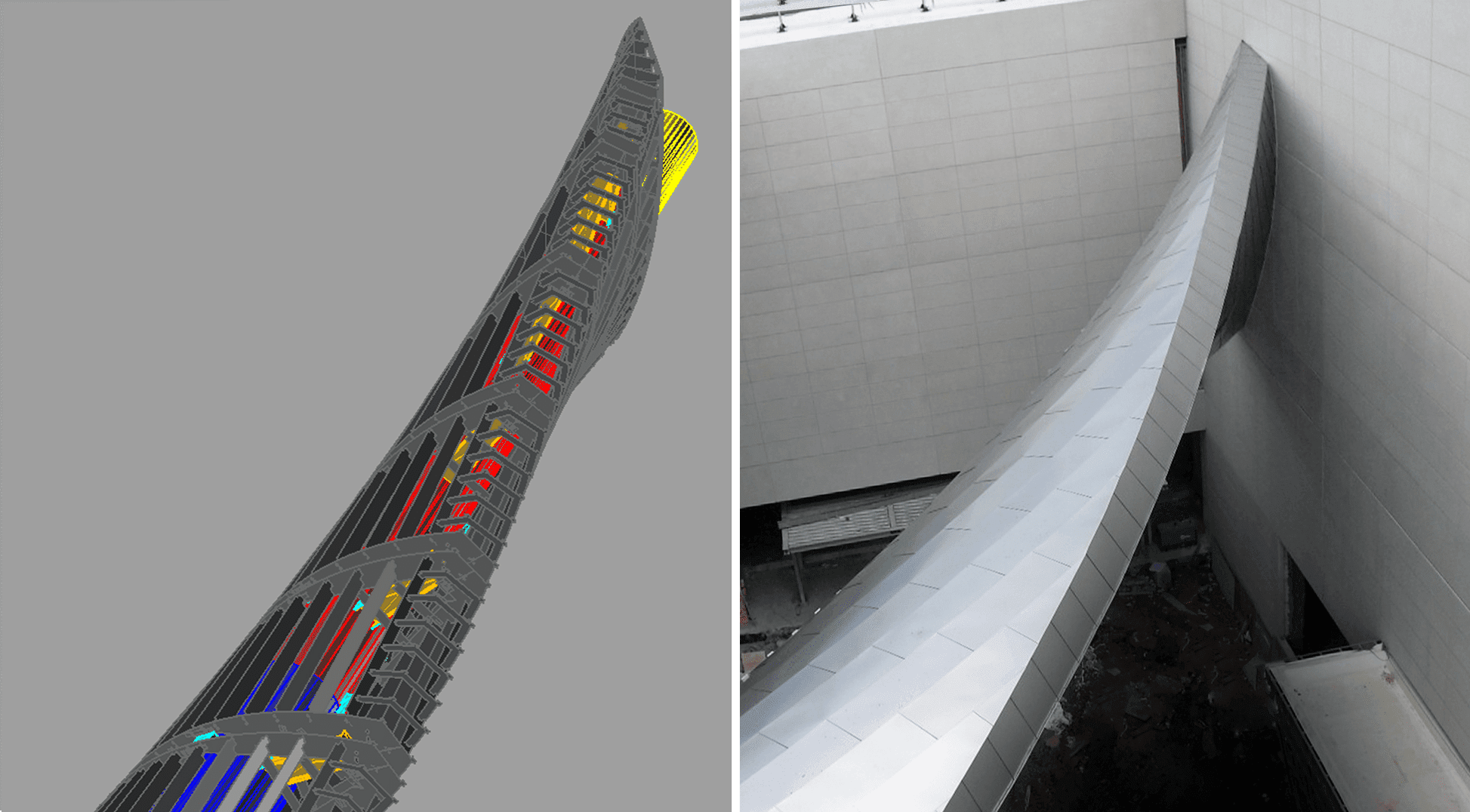

Elkus Manfredi Architects designed the facade’s undulations with perspective in mind. When travelers drive by, the structure appears animated and kinetic, an effect caused by the way the facade curves in and out. Zahner worked with the architects to design a curving facade panel system that is both aesthetically powerful as well as economically effective.

The skin is actually three different tones of colored stainless steel. Two of these tones were formed by a electro-chemical process which permanently changes the tone of stainless steel. Zahner has used this process for several other projects, including the Contemporary Jewish Museum which has a dark blue interference coating and a cross-fire brushed pattern. Interference stainless steel was also used on the The EMP Museum, The Meyer Fletcher Residence, and the Royals Crown at Kauffman Stadium.

In addition to providing the exterior scope, Zahner also manufactured interior metalwork for the department store interior entrance. This interior wall uses a similar subtle curvature made in a lightweight ZEPPS framework. This scope included the ceiling area, made in a stainless steel with standard polish.

The exterior scope included various metal details, including the soffit at the Neiman Marcus entrance and the throughout areas underneath the facade’s curtain. Providing these standard details for the facade and other areas is typical of Zahner scope. The company routinely handles interior and exterior standard metalwork on a variety of projects.

Designing the complex curtain system for the Neiman Marcus facade was made possible through Design Assist. Zahner worked with the architects at Elkus Manfredi to develop a design, mockup, and manufacturing process to efficiently fabricate, deliver, and install the exterior metal facade.

Photo ©

Photo ©

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

PHOTO ©️ Parrish Ruiz de Velasco (parrch.com)

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.

Ɱ, Creative Commons Attribution-Share Alike 4.0 International license, edited.